Augmented Reality and Extra Layers of Touch and Feel

Pioneering cobots from Universal Robots, working in tandem with the operator, can now integrate interactive augmented reality into labor intensive tasks and improve jobs that are prone to human error.

Posted: March 2, 2017

In Booth 1245, Universal Robots USA, Inc. (Ann Arbor, MI) will exhibit a wide range of new applications showcasing the game-changing benefits of their pioneering cobots, including demonstrations developed in collaboration with Kubica Corporation (Novi, MI), a Preferred Systems Integrator of UR robots that will showcase an interactive augmented reality application featuring a UR10 robot assembling a door panel with assistance from a Light Guide System (LGS) from OPS Solutions LLC (Wixom, MI), an augmented reality tool that is transforming manual assembly and manufacturing processes. By projecting a digital operating “canvas” directly onto the workspace, LGS combines the best of human intelligence and automation technology to direct the robot and the operator through the required assembly tasks.

“We chose to show a door panel build because it is a labor intensive process that is prone to human error, which is now significantly reduced by having the UR cobot handle several of the assembly tasks, working in tandem with the operator,” noted Scott Lown, a controls engineer with Kubica. “We found that the UR10 cobot has some built-in features that make it the perfect robot to accomplish this task.”

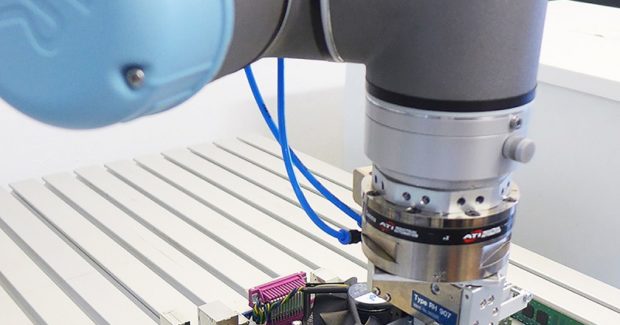

ATI Industrial Automation (Apex, NC), a developer of robotic tool changers and force/torque sensors, will add an extra layer of touch and feel to the UR cobots at the show, which will be the launch pad for their new Axia80 low cost multi-axis force/torque sensor embedded with a UR5 robot in an interactive booth demonstration, where attendees will be able to move a workpiece that will force the cobot to adjust its path while it maintains a constant force. The Axia80 force/torque sensor has all the electronics built into the transducer body to keep the cost down and footprint smaller, while excelling in accuracy, resolution, and robustness. Unlike load cells that only operate on a single axis and measure only push, the Axia80 senses torque and side loads along all six axes. A UR robot doing assembly with force control will make decisions based on that force feedback and change its motion to get the assembly accomplished, changing path with the environment instead of following a preprogrammed path.

“It’s similar to a handshake,” said Robert Little, the chief executive officer of ATI. “The force/torque sensor measures the touch and feel and gives life to robots. It’s a feedback mechanism. For factories wanting to get deeper into automation, the cobots can use these sensors to do more of what those human laborers accomplish in terms of dexterity and efficiency.” The new force/torque sensor is in the process of being included in the Universal Robots+ online showroom that features a wide selection of end-effectors, software and accessories, all designed to work flawlessly with UR robots. “The UR+ platform will allow us to fully integrate our Force/Torque Sensors with their robots, making it very easy for users to program force-guided applications,” added Little. Around 15 other UR+ solutions will also be showcased in the cobot pioneer’s booth.

Universal Robots USA, Inc., 5430 Data Court, Suite 300, Ann Arbor, MI 48108, 844-462-6268, ur.na@universal-robots.com, www.universal-robots.com.