Digital Production Management and Cryogenic Machining

Several machine tool builders are demonstrating the shop floor cost savings and production improvements of machining with cryogenic technology and digital production management from 5ME.

Posted: March 22, 2017

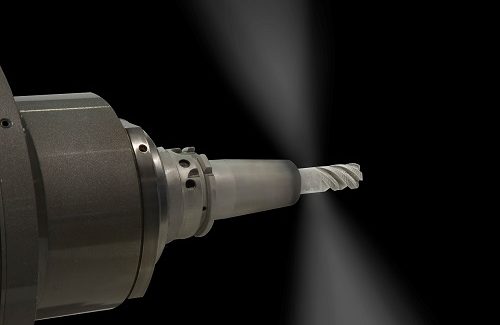

5ME® (Cincinnati, OH) has joined forces with several machine tool builders to demonstrate the cost saving and better production benefits of cutting with their cryogenic machining technology and digital production management of the shop floor. Their unique, multi-patented cryogenic machining process is a breakthrough technology that enables higher cutting speeds for increased material removal and longer tool life by transmitting liquid nitrogen at ‑321 deg F through the spindle/turret and tool body, directly to the cutting edge. This environmentally friendly machining technology increases throughput, part quality, tool life, and profitability while reducing energy consumption. It also provides a healthier, safer work environment through the elimination of traditional water-based or oil-based coolants.

5ME aims to launch cryogenic machining technology across numerous Mazak platforms and create a unique “designed for Cryo” machine tool by 2019 to coincide with Mazak’s 100-year anniversary. The revolutionary VARIAXIS i-800T 5-Axis VMC with cryogenic machining technology has a trunnion table and turning capability to manufacture high-value titanium aerospace engine components. Cryo technology is already offered across numerous Okuma platforms, such as the MU-8000VL 5-Axis VMC with trunnion table and turning capability that is particularly suited for processing tough materials commonly used in aerospace part production, such as blisks and aero engine components. 5ME and Okuma look to tackle difficult-to-machine alloys for the aerospace industry as they collaboratively expand the application of this technology. FFG MAG and their U.S. distributor, Star SU, offer 5ME cryogenics on the Boehringer VDF lathe platform.

https://youtu.be/j1ZS3jClSZ8

Okuma, Mazak, FFG MAG, Bosch Rexroth, NUM. Hydromat and Sunnen can all run the new Freedom 4.0 Smart Manufacturing IoT Platform from 5ME on their equipment using the new Freedom GatewayTM hardware appliance with Edge Analytics software. Freedom 4.0 features the new SmartBoard (Smart Dashboards) that is highly configurable so that users can create their own dashboards with the data they select, as well as the ability to embed images, websites, work instructions, and spec sheets. The Freedom software suite leverages the MTConnect standard and automatically extracts critical manufacturing data to produce web-based reports and analytics on asset utilization, availability, performance, quality and OEE. It is brand, asset and process agnostic. The software integrates seamlessly with ERP, MES, maintenance and quality business systems, and can be accessed anytime via smartphone or tablet device.

5ME, 4270 Ivy Pointe Boulevard, Suite 100, Cincinnati, OH 45245, 586-202-3285, pete.tecos@5ME.com, www.5me.com.