Heat Treating Surgical Components

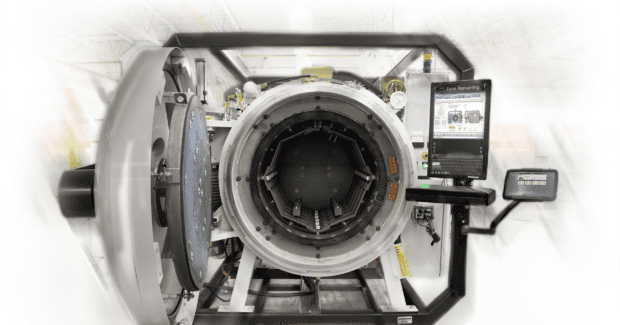

A TITAN H2 vacuum heat treating system with two-bar gas quenching from Ipsen satisfies the strict legal requirements of the medical industry.

Posted: March 23, 2017

Ipsen USA (Cherry Valley, IL) recently shipped a TITAN® H2 vacuum heat treating system with two-bar gas quenching to Costa Rica, where it will be used to manufacture surgical components. With its compact dimensions and superior quality, this furnace helps accelerate the pace of innovation while satisfying the strict legal requirements of the medical industry. This shipment included more than just a furnace, however, because the surgical parts manufacturer also utilized full-scale support that includes Ipsen U training, a spare parts kit, and installation/start-up support to advance their equipment and maximize uptime.

This standardized vacuum furnace features an 18 in x 24 in x 18 in (455 mm x 610 mm x 455 mm) all-metal hot zone with a 1,000 lb (450 kg) load capacity. It is capable of operating at temperatures of 1,000 deg F to 2,400 deg F (538 deg C to 1,316 deg C) with ±10 deg F (±6 deg C) temperature uniformity. Equipped with the PdMetrics® platform for predictive maintenance – which securely connects to a network of integrated sensors on the furnace to gather and analyze data, run algorithms and provide real-time diagnostics – this furnace provides sophisticated monitoring of critical systems and key parameters that improve the health and integrity of the equipment. The surgical parts manufacturer also received a gas backfill reservoir, a loader with a 2,000 lb (907 kg) load capacity and a complete air-cooled, closed-loop water system.

The surgical parts manufacturer decided to take a proactive approach to preventative maintenance by ordering one of the spare parts kits that consist of consumable and preventative maintenance items to help ensure equipment uptime and keep the furnace running smoothly. They also opted for technical support and training, including installation supervision, start-up service and seats at Ipsen U – a three-day course that provides a broad overview of furnace equipment, processes and maintenance using a hands-on approach to learning.

Ipsen USA, 984 Ipsen Road, Cherry Valley, IL 61016, 815-332-4941, Fax: 815-332-4549, www.IpsenUSA.com/titan.