Top Five Reasons Spreadsheets Are Dead Weight

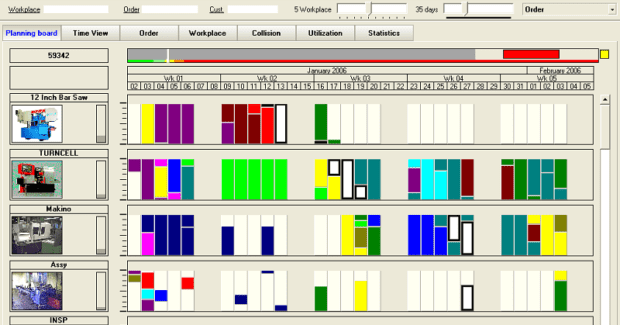

JobPack scheduling software from Shop Floor Automations analyzes current jobs and machine capacity to determine job status and estimate completion.

Posted: March 22, 2017

Spreadsheets are still pretty prevalent on shop floors, and it’s understandable. They’ve been a long standing part of the manufacturing operations and offices in many job shops, metal service centers and contract manufacturing sites. However, sticking to this enduring method could be costing your operations productivity. Learn how to stop relying on spreadsheets: As a prominent automation solutions provider for manufacturing shop floors since 1998, Shop Floor Automations, Inc. (SFA; La Mesa, CA) provides job scheduling solutions via their JobPack software. They detail five reasons why spreadsheets on shop floors are outdated and killing productivity, and why your shop floor should make the change from spreadsheets to a real-time, graphical job scheduler:

- Reason One: No ROI for time spent on spreadsheets. You are spending time manually noting information on a spreadsheet, plus doing related administrative work, such as filing and searching for work order data info. If you have an operation with more than a couple of machines and more than a handful of employees, this is time wasted. Instead, you could have software with real-time insight from your production schedule that shows capacity usage and keeps jobs running on time.

- Reason Two: Data entry errors require revisiting. Have you or an employee ever needed overtime approved to fix errors with spreadsheets? This is more time, resources and money spent on fixing human errors. Instead, there is software that will help with data entry, for example, no duplication errors from entering work times. You will also have day-to-day planning data based on real-time capacity vs. guesswork based on previous spreadsheets.

- Reason Three: Control-F isn’t the answer. If you are looking for specific info in a spreadsheet, it is likely you need to remember data from a certain tab, or you go tab-to-tab and press good old “Control-F” to find the info you think you are looking for by keyword. You especially can’t use Control-F if you print all of the spreadsheets and file them away while never saving the digital copies (perhaps due to lack of storage space on an old computer). Instead, particular software programs can now help you access work orders and look at job status immediately, without spending more time sifting through information.

- Reason Four: You dread growth because it means more paperwork. A spreadsheet is not going to be able to adjust by itself when you get new jobs in or when a job is canceled. A spreadsheet also isn’t going to tell you when there are issues with a machine causing a bottleneck. It’s an especially bad situation if you receive a last-minute rush order from a big client and you feel like you have to turn it down because you don’t want to spend the time figuring out how to re-organize jobs. Job tracking, planning and scheduling combined into one simple interface will help your production operations run more efficiently and meet or surpass promised due dates.

- Reason Five: Machinists are not office clerks. There is a sizable skills gap in manufacturing that will be filled slowly over the next few years, and asking a qualified machinist to spend time helping with redundant paperwork that automated software could be doing for you is not in your best interest. They want to be able to get their hands dirty, create and contribute to a $2 trillion “Made in America” industry. Asking them to struggle with spreadsheets is unfair to them when their rare talents can be used elsewhere. User-friendly software only requires a few button pushes for operators to provide immediate feedback on current job statuses.

The bottom line here is that job scheduling software is crucial for knowing if deliveries will be on time. It takes current jobs, along with machine capacity, and provides the ability to see where your jobs are plus when they are going to be completed. Unexpected downtime on machines will be accounted for and re-scheduling that is based on new machine capacity can occur. With a reliable, real-time scheduling system in place, you’ll be better equipped to update valued customers on delivery dates and identify late jobs before they happen so you have time to prepare or fix it. Displays of pre-order and estimated costs, as well as actual costs incurred during manufacturing, are shown as they occur, which is of added value.

Shop Floor Automations, Inc., 5360 Jackson Drive, Suite 202, La Mesa, CA 91942-6003, 619-461-4000, www.shopfloorautomations.com.