Metrology Systems for Precision Measurement of Parts and Assemblies

The latest precision dimensional measurement machines and software from QVI includes metrology systems that combine proprietary optical, laser, and contact sensors for precision measurement of manufactured components and assemblies.

Posted: April 19, 2017

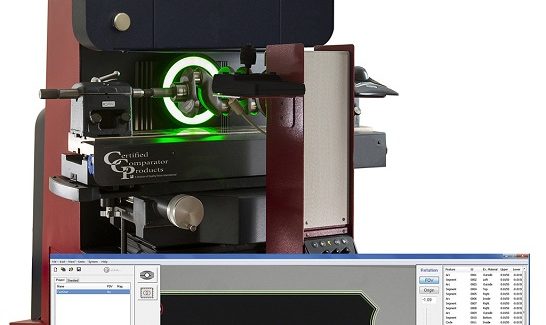

In Booth 3003, QVI® (Quality Vision International; Rochester, NY) will exhibit and demonstrate their latest precision dimensional measurement machines and software, including metrology systems from OGP® (Optical Gaging Products), RAM Optical Instrumentation, CCP (Certified Comparator Products) and Itaca that combine proprietary optical, laser, and contact sensors for precision measurement of manufactured components and assemblies.

OGP will exhibit their Fusion 400 large-field-of-view multisensor system that offers automated measurement and maximized throughput. Fusion optics provide two magnifications. Low Mag facilitates fitting multiple parts into a single 100 mm field-of-view. AutoMeasure analyzes any part and displays its geometry without a programmed measurement routine. With AutoID, previously programmed parts may be placed anywhere on the stage and Fusion will identify them and their orientation and automatically measure them. High Mag allows up-close measurement of small features. Multiple sensors may be deployed rotationally so that full stage travel is measurement-accessible. OGP will also demonstrate the technology of an articulating Multisensor Bundle on a large volume measurement platform. This self-contained bundle, powered by QVI ZONE3® 3D CAD-based metrology software, can rotate, deploy, and bring to bear a number of measurement sensors. www.qvii.com/ogp

RAM will exhibit their QVI SNAP™ 350 large area digital measuring machine that provides up to a 100 mm field of view with an expansive 350 x 350 mm XY travel to automatically measure large parts with critical details, or numerous small parts. AutoID automatically recognizes and measures all parts within its measuring area, even multiple different parts. Zoom Anywhere™ lets you zoom in to measure fine details anywhere in the field of view. SNAP 350 offers available motorized 150 mm Z-axis motion with video autofocus, optional touch probe for high accuracy Z-axis measurements, and a new DRS off-axis laser option. www.qvii.com/ram

CCP will exhibit their c-vision Video Contour Projector®, the ultimate shop floor measuring system. Its rugged design and high load capacity put advanced automatic video measurement capability to work on the shop floor. It features a telecentric dual magnification optical system with advanced digital imaging technology. New vCAD™ Virtual Chart Gage software that allows direct comparison of parts to CAD files is standard, and fully automatic Measure-X® 2D metrology software is optional. www.qvii.com/ccp

Itaca will exhibit their FlexGauge T-16 high accuracy tactile 3D gauging system that offers an industrialized and rugged alternative to custom gauging products. It is specially tailored to measure small precision parts, such as gears, valve bodies, CV joints, racks and ballscrews. With its granite structure stability, built-in thermal compensation and air bearing motion, FlexGauge is at home on the manufacturing floor or in the QC lab. The T-16 may be configured with single or dual probes, with available touch trigger or continuous contact scanning probe. Flexible metrology software is included. www.qvii.com/itaca

Quality Vision International, Inc., 850 Hudson Avenue, Rochester, NY 14621, 585-544-0450, info@qvii.com, www.qvii.com.