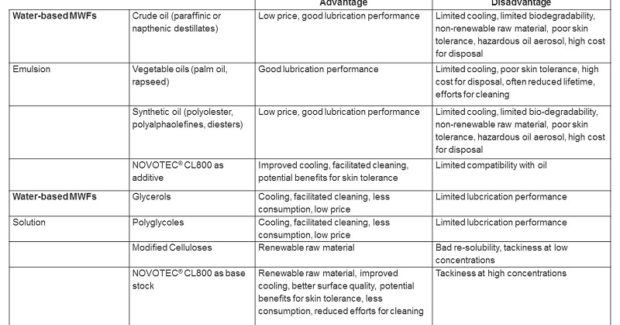

Proteins: A Cutting Edge Clean Technology Additive for Metalworking Fluids

How can a shop reduce their operating costs when they face the challenges of machining difficult-to-cut metals and temperature-resistant super alloys, improving employee safety, and being more environmentally friendly? One solution lies in proteins . . . yes, that’s right, proteins.

Posted: April 24, 2017

Total global consumption of metalworking fluids (MWFs) is expected to reach around 2.8 million tons by 2020, with increased use of special alloys and demand for more high performance fluids. For example, the automotive industry is using aluminum and titanium as lightweight alloys for fuel efficiency, while aerospace and other industries introduce more difficult-to-cut metals and temperature-resistant super alloys.1 With certain industry mandates to eliminate hazardous performance additives (chlorinated paraffin and boronic acids) and biocides (formaldehyde releasers) from MWFs, metal fabricators and machine shops are seeking more natural alternatives that do not compromise performance and efficiency. As competitive innovations shift them toward a broader and more diverse range of metals, these shops demand MWFs to keep pace.

That’s not all: The paramount importance of user safety and well-being demands improved environmental friendliness and user safety, whether in the form of air quality, reduced oil-contaminated waste or skin protection. And shops must still find ways to reduce processing costs – including those of MWF disposal, because with traditional MWFs the re-processing of metal flakes is hindered as the oils of the MWFs adhere to the flakes. What can possibly help shops address all of these issues? Proteins . . . yes, that’s right, proteins.

THE NOVOTEC EFFECT

Proteins are a key performance factor in complex biological systems like the human body, where proteins help lubricate joints, stabilize bones and protect the skin. By transferring the technical knowledge of protein production to metalworking applications, functional proteins can combine efficiency advantages with health and environmental friendliness in MWFs to help shops improve their productivity and efficiencies and reduce costs, all while being friendly to the environment and operators alike.

NOVOTEC® is a new class of functional proteins that changes surface technology from hydrophobic (water repelling) to hydrophilic (water attracting). Scientists have discovered proteins that attach firmly to surfaces such as metal or glass. The molecules combine with each other to form a stable, resistant layer. As water hits the surface, the protein layer attracts water and creates a smooth, hydrophilic surface coating. From this, NOVOTEC CL800 has been developed as an additive for water-based MWFs where the proteins form lubricating layers of hydrated protein chains that facilitate cooling and protect surfaces from wear and offer reduced consumption and increased skin tolerance.

Traditional MWFs use a combination of oil or synthetics for lubrication and water for cooling. With oil, cooling performance is limited as the emulsified oil hinders the water to effectively dissipate heat from surfaces. As a result, residues from cracked mineral oil and oxidized metal alloy are created at the surface of machined tools. Additionally, skin contact often results in irritation or a more severe allergic reaction due to the surfactants needed to stabilize the oil in the emulsion. Several fully synthetic MWFs have been developed based on water soluble lubricating polymers like polyglycols. However, the lubrication performance of these polymers is limited because the water soluble polymers are not absorbed effectively to the surface.

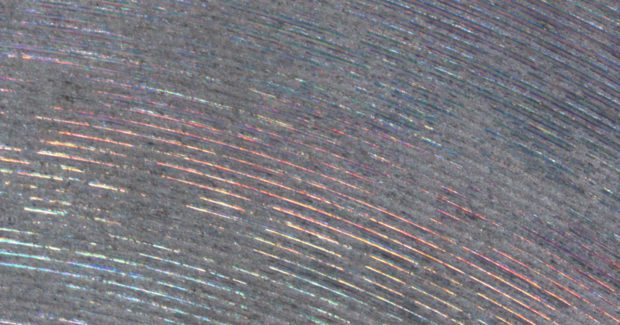

In contrast, NOVOTEC CL800 is a protein-based liquid concentrate that can be used as base stock or performance additive in water-miscible MWFs. It is comprised of natural polyfunctional protein molecules and provides strong intermolecular interactions with water and numerous application surfaces (steel, glass, aluminum, etc.). Use of this protein-based liquid concentrate allows an efficient combination of cooling capacity and lubrication performance by providing a highly water soluble biopolymer that also has a strong affinity for numerous surface types. The end result is more efficient heat transfer during metalworking and a better surface quality of machined parts. Processed parts can often be used for further production without the need for subsequent intensive cleaning, provided that they do not need conservation against corrosion.

Because NOVOTEC CL800 is produced from pure collagen, it has an excellent toxicological profile and can help to improve the skin tolerance of MWF formulations (see Chart 1). It is inactivating formaldehyde releasers, which ensures that these biocides are not used for the stabilization of the new MWFs. This means formulators are either using more modern biocides, such as Benzisothiazolinone (BIT) and/or Methylisothiazolinone (MIT), in order to stabilize MWF concentrates or they switch to biostable formulations without additional preservatives. Like all synthetic water soluble MWFs, NOVOTEC CL800-based MWF needs an effective water soluble corrosion inhibitor. The better surface quality and improved cleanliness of the machined parts makes it even more important that the MWF containing NOVOTEC CL800 has an effective corrosion inhibitor for protection.

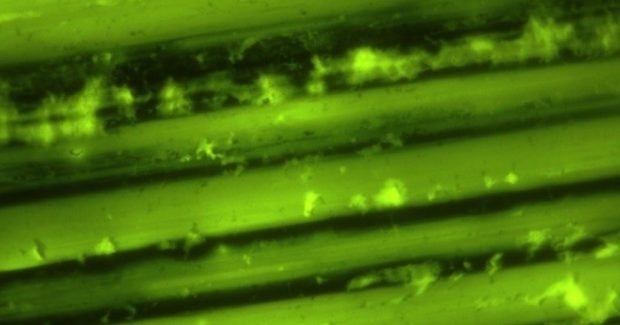

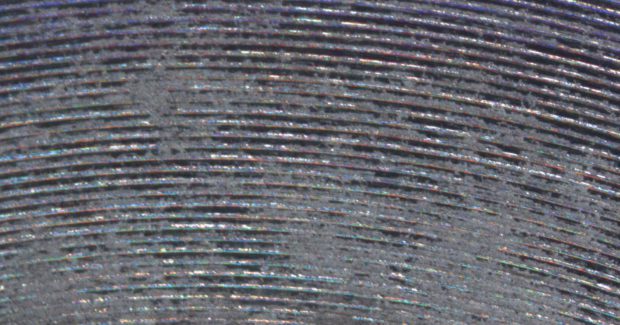

NOVOTEC CL800 is prepared from collagen material, including hydrolyzation and extraction processes followed by subsequent enzymatic treatment to achieve proper functionality and molecular size. The protein molecules of this protein-based liquid concentrate are high in hydroxyproline content. This amino acid is not found in other protein species, such as plant protein or milk protein, and it gives NOVOTEC CL800 a unique and much more polar structure that allows a fast absorption to metal surfaces, especially steel. To prove this mode of action, NOVOTEC CL800 was combined with a UV-marker so that the protein film on a surface was directly visible via a fluorescence microscope. Figure 1 shows the microscopic image of Fluorescein-marked NOVOTEC protein molecules (green) bound on a steel surface.

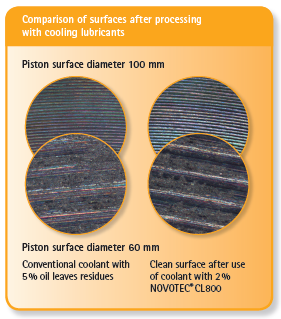

Various experiments were conducted, including wear resistance tests with a Cross-Cylinder-Tester (XTC) apparatus according to Reichert setup. The main axes of the ellipse shaped scars (worn areas) were measured. NOVOTEC CL800 was compared with various mineral oil-based products and synthetic fluids. Even a pure dilution of 5 percent NOVOTEC CL800 in water without any further additive resulted in the same low Reichert value as 5 percent of a standard synthetic fluid tested and left no residue (see Figure 2).

In cooperation with Theodor-Frey-Schule technical college (Eberbach, Germany), researchers studied pressure resistance. A piston (AlSi12) with a diameter of 105 mm was placed in a metalworking lathe. A hole was drilled in the middle of the piston and then machined from the inside to the outside at constant rotation speed (1,000 U/min, feed 0.19 mm). The surface of the piston machined with the mineral oil-based product was completely blocked by welded material, while the NOVOTEC CL800 prevented the material from welding under the same conditions due to the nature of the protecting protein films and the better cooling performance (see Figure 3).

Because NOVOTEC CL800 is not a standalone solution for MWFs, we worked together with other additive producers such as LANXESS Rhein Chemie Additives (Cologne, Germany), an expert in the area of high-performance additives for lubricants, to develop a guideline formulation for a MWF with NOVOTEC CL800. Among the first MWF producers using NOVOTEC CL800 in a commercially available MWF was Chemische Werke Kluthe GmbH (Heidelberg, Germany), which developed and now actively markets their own NOVOTEC CL800-based product, Hakuform A805.

G+F Sondermaschinenbau GmbH (Beerfelden, Germany), a manufacturer of special machinery and equipment for the food, beverage and printing industry, was the first to test Hakuform A805. Their employees and machine tools deal with a variety of materials (brass, aluminum, steel and stainless steel) and machining steps (sawing, milling, drilling and turning). After extensive and diverse testing with Hakuform A805, G+F reported performance efficiencies that included improved surfaces, especially when machining non-ferrous metals, longer life of saw blades, little foaming – even at high pressure (20 bar), and an elimination of residues – even without an ion exchange system. Operator benefits were equally positive. Those with known allergies to conventional MWFs could use Hakuform A805 without reaction. Even operators without known reactions to traditional fluids expressed a higher skin tolerance to the NOVOTEC formulation. The G+F Beerfelden shop changed all of their machines to Hakuform A805 MWF in January 2015.

In another field test at Heidelberger Druckmaschinen AG ((Heidelberg, Germany), the shop used Hakuform A805 in turning and milling of steel, stainless steel, aluminum, non-ferrous metals and composites. Besides increased tool life and a broad suitability for different materials, they reported less consumption of metalworking fluids, fewer equipment maintenance issues, and easier cleaning of machines and equipment parts. Users also reported a notable improved skin tolerance, even compared with full synthetic MWFs. Heidelberger Druck is now installing a central supply system for Hakuform A805 to run this MWF on several machines in their technical training center.

A CUTTING EDGE SOLUTION

By using NOVOTEC CL800, manufacturers of MWFs can generate products that address the challenges of modern metalworking and offer improved cooling and lubrication that decreases wear on equipment, lowers maintenance costs, improves skin tolerance, and reduces chemical vapors and odor. Efforts for daily cleaning of machine tools can be reduced significantly because they can be cleaned with the cooling lubricant itself. MWFs like Hakuform A805 have provided immediate and significant benefits for those shops that seek all-around performance improvements, as opposed to optimizing a singular component of their processes. Manufacturing environments that experience irregular downtime or do not have machine tools with proper exhaust ventilation are also ideal candidates for these MWFs. And any shop where operators cannot avoid direct skin contact with MWFs and/or are working to avoid or reduce oil pollution in their factories or surrounding environments can realize improvements.

NOVOTEC CL800 is still not fully competitive in pricing compared to existing water-soluble lubricants such as polyglycols, but it offers better cooling and lubrication performance, allows decrease of AW additives and gives rise to less aggressive formulations. Field tests show a decrease in consumption of up to 40 percent compared to mineral oil based products, due to better cooling and less discharge via flakes. In case of subsequent processing steps, such as coating, phosphating, painting, gluing or welding of the processed parts, NOVOTEC CL800-based MWFs can significantly reduce overall production cost and process time because the cleaning of the processed parts from oil residues is no longer necessary.

References

1. Source: https://www.nynas.com/de/media/newslist/growth-opportunities-in-the-mwf-market