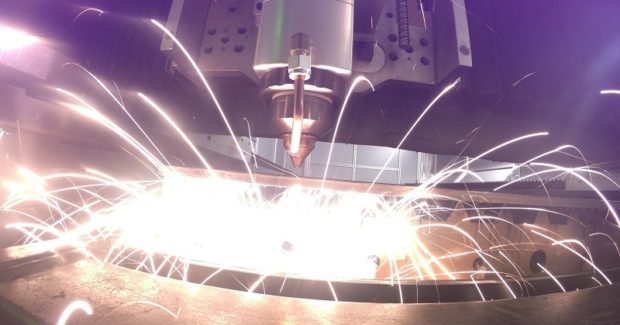

Air Assist Cutting Increases Cutting Speed, Lowers Production Costs

With its human-machine interface and user-friendly touchscreen controls, the CL-960 6 kW Fiber Laser from Cincinnati Incorporated uses advanced laser cutting capabilities to process thin material faster while cutting up to 3/4 in thick steel.

Posted: May 29, 2017

The new CL-960 Fiber Laser from Cincinnati Incorporated (CI; Harrison, OH) introduces a clean new look with productivity enhancements, including air assist cutting capabilities that are ideal for the many instances where air can be a cost-effective assist gas alternative to nitrogen or oxygen. Engineered for manufacturers requiring fiber laser precision and speed, the CL-960 processes thin material faster while cutting up to 3/4 in thick steel. Air assist cutting and reliable linear drive motors boost productivity while lowering production and maintenance costs. With its human-machine interface (HMI) and user-friendly touchscreen controls, the intuitive CL-960 allows operators of all levels to maximize the machine’s advanced laser cutting capabilities.

Additional features include a 6 kW light source, dual pallet configuration, fiber resonator technology, flexible glass fiber beam delivery, table sizes of 5 ft x 10 ft / 6 ft x 12 ft / 8 ft x 20 ft, and interfaces with a modular material handling system. “Shops are continually challenged to meet accelerated production schedules, rigid quality standards and increase throughput, all while controlling costs,” noted Cincinnati product manager Todd Kirchoff. “In addition to high precision, the CL-960 Fiber Laser leverages air assist cutting technology by substituting air as an assist gas in place of nitrogen. This has two key advantages: lower operating costs and higher cutting speeds. While others are relatively new to this approach, we’ve been leading the way with air assist cutting for more than ten years.”

Cincinnati Incorporated, 7420 Kilby Road, Harrison, OH 45030, 513-367-7100, info@e-ci.com, www.e-ci.com.