High Torque Retention Knobs Increase Productivity, Reduce Downtime

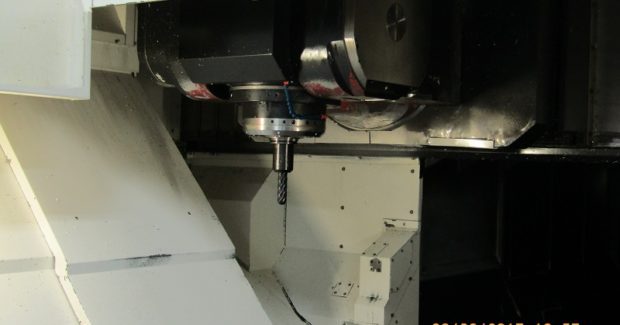

Hansen Engineering uses High Torque Retention Knobs from JM Performance Products to reduce downtime, extend tool life, and increase speed and feed rates in their machining of aerospace components.

Posted: May 31, 2017

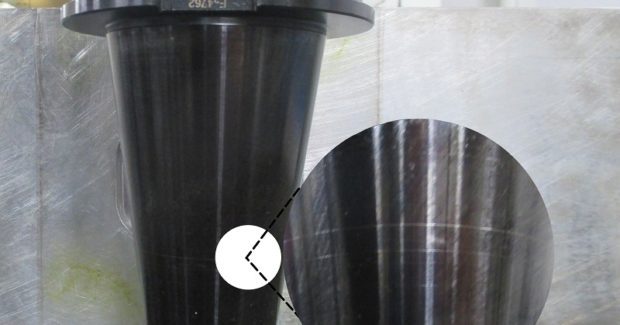

The easiest and most cost-effective way to achieve the highest level of performance from existing CNC mills and tooling is to eliminate toolholder expansion that occurs when a standard retention knob is installed into a toolholder. Pressure exerted by thread engagement, coupled with the elastic properties of the steel used to manufacture the toolholder, creates a bulge at the small end of the holder. Once expansion occurs, the holder will not pull all the way into the spindle and it cannot make contact with upwards of 70 percent of the spindle surface. Because this bulge stops the toolholder from making full contact with the taper of the spindle, a wide range of CNC milling issues can surface: vibration and chatter, poor tolerances, non-repeatability, poor finishes, shortened tool life, excessive spindle wear and tear, run-out, and shallow depths of cuts.

By eliminating the bulge and subsequent problems, reduced downtime, extended tool life, and increased speed and feed rates can be realized on existing machinery. Recognizing the design flaw inherent in CNC V-flange tooling that was responsible for costly CNC milling and boring issues, JM Performance Products, Inc. (JMPP; Fairport Harbor, OH) designed their patented High Torque Retention Knob that can be used in existing toolholders to eliminate the bulge. One leading aerospace engineering shop, Hansen Engineering Company (HEC; Harbor City, CA), has embraced these High Torque knobs to overcome their ongoing production issues.

Established in 1962, HEC is an approved Air Transport Association (ATA) supplier of precision machined parts, assemblies, and major structural assemblies that specializes in complex MDI surface geometry, statistical process control, and electronic probing of part surfaces. Two buildings on their 43,000 sq ft campus boast a wide array of major CNC equipment that includes high speed and heavy duty 5-axis and 3-axis machining centers, horizontal machining centers with dual tombstones, and one 5-axis machine with dual shuttle tables. By converting to High Torque knobs in these 14 CNC machine tools (requiring approximately 120 total High Torque retention knobs per machine), HEC has realized an approximate 15 percent increase in productivity and decrease in downtime, respectively.

The majority of these machine tools operate within a 10,000 rpm to 15,000 rpm range, cutting large blocks of titanium, stainless steel, and aluminum at high speeds for a wide array of aerospace parts. Before the new knobs were used, toolholders were getting stuck in the spindle due to deformation factors evidenced by wear marks at the top and bottom of the holders, fretting appeared on contact surfaces, and increasingly long cycles developed. These persistent problems led to increased production shut downs to allow the machines to cool off for significant periods of time. Additionally, poor finishing and chatter problems were recurring when roughing aluminum, titanium, and stainless steel for forging jobs.

HEC engineers were shown how the High Torque retention knobs would work with their 50 taper V-flange toolholders: the knob is longer and reaches deeper into the holder’s threaded bore such that all thread engagement occurs in a region of the toolholder where there is a thicker cross-section of material to resist deformation. HEC initially bought 25 of these knobs and properly installed them, following calculated torque specs and using a retention knob socket and torque wrench. They immediately noticed a five percent spindle load decrease using a 3 in hi-feed insert mill running titanium. They also installed them on an aluminum forging job they were running that had consistently produced chatter problems. Among the tools tested for this job were a 1-1/4 in diameter knuckle rougher and 2.0 in diameter finisher.

“Again, the results were positive as the chatter was eliminated and it produced the best finish we have ever seen on these parts,” said Curtis Sampson, the shop leadman at HEC. “After that, we bought 50 more pieces and immediately noticed improvements all around the table. We’ve been increasing their use over time ever since.” In noting the progressive conversion over time for the machines since these initial tests, the buyer for the tool crib at HEC, Jose Campos, stated, “Productivity has continued to increase by approximately 15 percent. The same rate applies for downtime, as there is less change out of tool cutters across the board.”

Campos also provided a key example of one machine running at a speed of 10,000 rpm, 350 ipm feed on aluminum parts. In 2015 they used 170 High Torque retention knobs for the year, in 2016 they used 300 High Torque knobs. He also noted usage on their newest Mazak 5-axis CNC machining center that features 160 in length with dual shuttle tables and a tool changer designed to run one table full of parts while the other is being loaded to eliminate down time. “Our Mazak machines used to make a loud noise when changing tools, but the High Torque retention knobs solved that problem,” noted Campos. “The machines are much quieter now when roughing titanium and stainless steel. They also eliminated fretting of the toolholder shank.”

High Torque retention knobs are longer than traditional retention knobs, with a precision pilot to increase rigidity and a relief below the flange that forces threads into a deeper cross section of the toolholder. The knobs are hard turned to ensure precision fit and are balanced by design with threads cut to start and finish 180 deg from each other. These will work in existing toolholders. For HEC’s demanding aerospace production, these retention knobs have shown lower spindle loads, which is better for the machine. When roughing titanium and stainless steel with the knobs, there was a significant reduction in power consumption and overall tool life was improved. Over the long haul, their shop has been able to increase speeds and feeds that deliver better cycle times to realize substantial savings.

JM Performance Products, Inc., 1234 High Street, Fairport Harbor, OH 44077, 440-357-1234, Fax: 440-357-1129, www.jmperformanceproducts.com.