Extremely Effective Resistance Welding Gun for High Strength Steel Applications

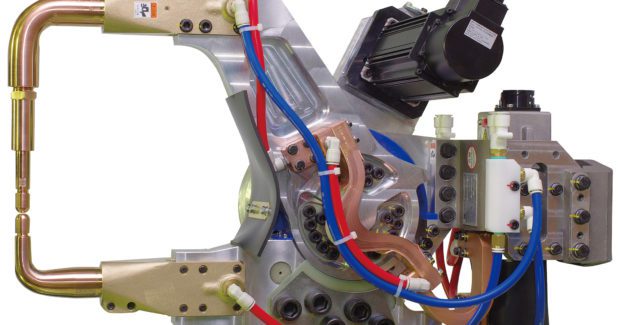

The maintenance-free reduction gear drive unit on the High Force Lightweight Reduction Gear X-Gun from Dengensha America adapts with a high speed servomotor for production efficiency on Fanuc, Nachi, Yaskawa, Kawasaki, Kuka and ABB robots with small footprints.

Posted: May 5, 2017

The High Force Lightweight Reduction Gear X-Gun from Dengensha America Corporation (Bedford, OH) is extremely effective for high-strength steel applications. Lighter in weight and with a smaller frame, users can count on production efficiency. With its new high torque reduction gear, this gun is capable of an electrode force ranging from 4.8 kN to 7 kN.

The High Force Lightweight Reduction Gear X-Gun has a proprietary lightweight design that integrates a new structure, an optimal layout of primary parts, and a gun arm made from aluminum, combining to achieve a total weight that is much lighter, ranging from 90 kg to 97 kg. This same proprietary design enables the new Reduction Gear X-Gun to operate seamlessly with the newly developed heavy duty lightweight MFDC transformer. Users can count on a maintenance-free reduction gear drive unit that is adaptable with a high speed servomotor. The Lightweight High Force Reduction Gear X-Gun is compatible with Fanuc, Nachi, Yaskawa, Kawasaki, Kuka, and ABB robots with a small footprint.

Dengensha offers automotive, agricultural and general manufacturers one of the most complete lines of resistance welding equipment in the world, including projection and spot welders; weld guns, feeders and controls with consumables; and spare parts. Training and field service complete their single-source capabilities.

Dengensha America Corporation, 7647 First Place Drive, Bedford, OH 44146, 440-439-8081, Fax: 440-439-8217, sandrassy@dengensha.com, www.dengensha.com.