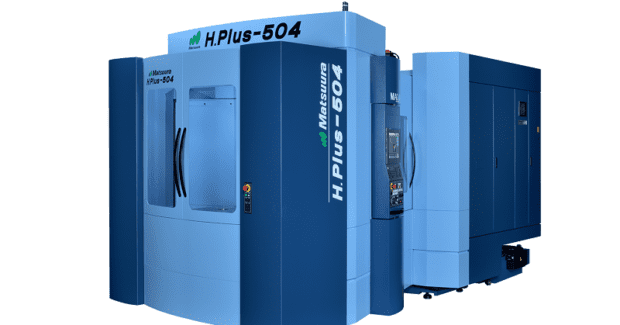

Reliable, Unmanned High Speed Horizontal Machining

With the largest working envelope in its class to handle 800 mm x 1,000 mm parts that weigh up to 750 kg, the high speed H.Plus-504 horizontal machining center from Matsuura Machinery USA is ideal for reliable unmanned operation, high accuracy and exceptionally efficient production.

Posted: May 30, 2017

For long periods of reliable unmanned operation, high accuracy and exceptionally efficient production, the H.Plus-504 horizontal machining center from Matsuura Machinery USA, Inc. (St. Paul, MN) provides high speed, rigidity, precision, reliability and low cost of ownership. The H.Plus-504 is equipped with a 500 mm x 500 mm pallet and #40-taper spindle. In response to demand for accommodating larger workpieces, the H.Plus-504 possesses the largest working envelope in its class to handle a maximum part size of 800 mm (D) x 1,000 mm (H), weighing 750 kg on each pallet. Along with the standard 12,000 min-1 spindle, a 20,000 min-1 (108.4 Nm) spindle for high speed machining and 15,000 min-1 (350.0 Nm) spindle for high torque, heavy duty machining are available.

A B-axis rotary indexing table is standard, driven by a direct drive motor with a maximum feed rate of 100 min-1. The DCS (Dynamic Clamp System) and ADC (Automatic Acceleration and Deceleration Control) intelligently contribute to shorter cycles and indexing times. The expandable ATC/APC options enable extended unmanned operation: tool storage capacity with a maximum of 330 tools (matrix type magazine) and pallet storage capacity with a maximum of six pallets (floor pallet system). The NC Matsuura G-Tech 31i is installed with the Matsuura Intelligent Meister System (MIMS) and utilizes a recently developed operation system (with a 15 in touch-panel screen) that improves operability, reduces non-cutting time and facilitates setup, operation and maintenance while saving labor and energy.

Matsuura Machinery USA, Inc. 325 Randolph Avenue, St. Paul, MN 55102, 651-289-9700, www.matsuurausa.com.