Sandvik Osprey Partners with Desktop Metal

Desktop Metal will offer Sandvik materials in their DM Studio and DM Production 3D printing systems.

Posted: May 12, 2017

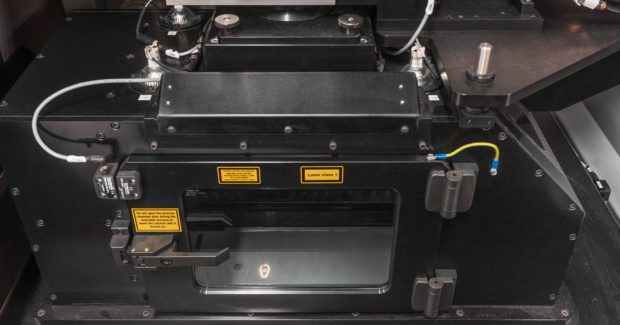

“We are an ideal partner to deliver the mass customization, quality and reliability in powder products that the 3D printing community is seeking.” (Photo courtesy of Sandvik)

Sandvik Osprey Ltd. (Neath, UK), a world-leading producer of gas atomized metal powders for advanced applications in net shape manufacturing, has announced they have formed a relationship with Desktop Metal, Inc. (Burlington, MA) to be a preferred supplier of a range of alloy powders for their recently-released 3D printing systems, the DM Studio™ and DM Production™ systems.

Desktop Metal is accelerating the transformation of manufacturing with end-to-end metal 3D printing systems. Founded in 2015 by leaders in advanced manufacturing, metallurgy, and robotics, they address the unmet challenges of speed, cost, and quality to make metal 3D printing an essential tool for engineers and manufacturers around the world. Fine, gas atomized powders are ideally suited to their technology, which delivers a highly loaded powder/binder mixture to the print head to achieve high density parts with low sintering shrinkage. Powders are clean and spherical leading to uniform flow and high packing density which is important for consistent parts build. The fine and controlled size distribution enables rapid sintering to high density resulting in excellent mechanical properties and good surface finish.

Sandvik Osprey has become a major supplier of fine gas atomized powders that has enjoyed global success in the fields of powder metallurgy and advanced materials. They make two main products: Metal Powders and Controlled Expansion Alloys. Fine gas-atomized metal powder products are used in a number of applications such as MIM (metal injection molding) parts manufacture, and now also increasingly in AM (additive manufacturing/3D printing) among other things. They have developed a huge portfolio of specialty alloys customized for specific clients, such as nickel- and cobalt-based super-alloys, as well as materials for aerospace and dental applications. They produce spray-formed controlled-expansion alloy components for electronics packaging and other advanced high-tech applications.

“We believe we have unrivaled experience and excellence in manufacturing diverse, fine powder products for the MIM (metal injection molding) and AM (additive manufacturing) markets,” said Richard J. Park, the managing director for Sandvik Osprey. “This makes us an ideal partner to deliver the mass customization, quality and reliability in powder products that the 3D printing community is seeking. Today we have a production capacity of more than 10 million lb and a product database exceeding 3,000 alloys. Atomizing expertise and metallurgical know-how are combined to give free-flowing metal powders and offer a comprehensive range of products from stainless steels to nickel base super alloys, cobalt alloys, tool steels, low alloy steels, copper and aluminium alloys and is able also to customize materials according to customer preferences.”

Park continued, “We are excited to be working with Desktop Metal and their world-class team of experts, and look forward to supporting the growth in demand for consumers of the new technology which we expect to come from all major industrial sectors. Our strength in materials science and atomizing technology is a perfect complement to their strengths in machine design and process knowledge.”

“With the launch of both our DM Studio and Production Systems, it’s critical our engineering customers have access to high-performance metal alloys for both prototyping and the mass production of metal parts,” added Ric Fulop, the chief executive officer and co-founder of Desktop Metal. “By partnering with world-class producers like them, we are able to broaden our catalog of materials to include the widest array of alloys, including advanced stainless steels, special alloys, titanium and other high-performance materials. Users who buy our consumables bearing the Sandvik and Osprey logos are guaranteed to benefit from high levels of quality and consistency that set their products apart as the productivity partner of choice.”

www.desktopmetal.com, www.smt.sandvik.com