How to Make Large Precision Measurements Simple and Affordable

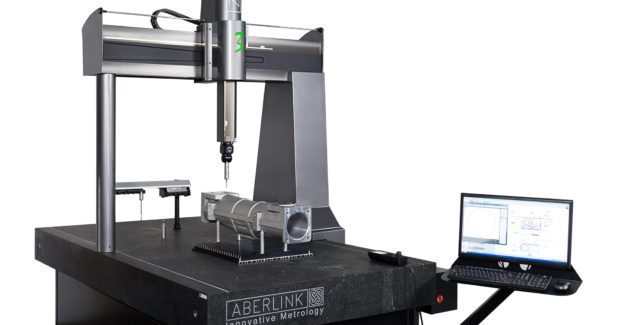

With greater air bearing separation for increased stiffness and accuracy, the new Zenith-3 CNC coordinate measuring machine from Aberlink USA can be supplied with any Renishaw touch trigger probe and probe head.

Posted: July 20, 2017

The Zenith-3 CNC coordinate measuring machine from Aberlink USA Inc. (North Branford, CT) is the result of a design evolution of their award-winning Zenith-too model of machines, taking into account over 20 years of CMM design experience. Many of the new improvements revolve around the right leg of the machine, which has been modeled after their very successful Azimuth machine. Greater air bearing separation now results in increased stiffness and has improved the accuracy of the CMM significantly. The first term error for this new model is more than a micron better than the Zenith-too. And all this comes with no cost penalty: the Zenith-3 CMM will continue to be sold at the same hugely competitive price that its predecessor was famed for, making large scale CMM measurements not only simple, but affordable.

The Zenith-3 can be supplied with any Renishaw touch trigger probe and probe head, including:

- MH20i / RTP20

- PH10T (wTP20, TP200)

- PH20

- PH10M (w/SP25)

- PH6M (wSP25)

Key features include:

- Aberlink’s revolutionary easy-to-use measurement software.

- Shortest learning curve of any equivalent system — one day without prior CMM experience.

- Smallest overall footprint of any comparable size CMM.

- Choice of Y-axis sizes, ranging from 1,000 mm to 3,000 mm.

- Suitable for the workshop environment.

- Protection from environmental vibrations as standard.

- Optimized friction free air bearings, all aluminum bridge and granite table.

- CMM touch screen joystick supplied as standard.

- Free stylus change rack with every motorized probe head upgrade.

Aberlink USA Inc., PO Box 645, North Branford, CT 06471, 203-208-0120, michael.uccello@aberlink.com, www.aberlink.us.