How to Use Dust Collection to Comply with OSHA’s Beryllium Standard

Job shops and other metalworking facilities affected by this standard must comply with most of the requirements by March 12, 2018 – they have less than two years to provide any required change rooms and showers and three years to implement engineering controls. Here’s why dust, mist and fume collectors are the best strategy to protect workers from the devastating pulmonary diseases associated with beryllium exposure.

Posted: July 17, 2017

OSHA’s new standard for beryllium exposure updates regulation to prevent chronic beryllium disease and lung cancer in American workers. The updated rule includes standards for general industry, construction and shipyards, which reduces the permissible exposure limit (PEL) and establishes a new short-term exposure limit. To comply with the new regulations, employers can use engineering and work practice controls to limit exposure to beryllium dust. High efficiency dust, fume and mist collectors are recognized engineering controls that help metalworking facilities achieve compliance and keep operators safe.

REDUCED PERMISSIBLE EXPOSURE LIMIT

Beryllium exposure occurs when beryllium and beryllium-containing materials are processed in a way that releases airborne beryllium dust, fume or mist into the workplace air. According to OSHA, approximately 62,000 workers are exposed to beryllium on the job every year. The new rule aims to sharply reduce both short-term and long-term beryllium exposure as follows:

- Short-term exposure limit: 2.0 µg/m3 over a 15-minute sampling period.

- Long-term exposure limit: 0.2 micrograms per cubic meter of air (µg/m3) over an eight-hour time-weighted average (TWA) work shift.

REQUIREMENTS FOR EMPLOYERS

OSHA requires employers to use engineering controls in areas that have high and low exposure to airborne beryllium. These controls include wet methods and/or ventilation to capture airborne beryllium and keep worker exposure below the new PELs. Along with providing respiratory equipment and personal protective clothing when necessary, employers are required to develop a written exposure control plan to demonstrate their procedures for achieving compliance. It must also list the engineering controls in practice to prevent exposure. Medical exams, health monitoring and recordkeeping are a requirement for employees who have exposure at or above the PEL or who show signs of beryllium-related health effects.

DUST COLLECTION TO MEET OSHA’S LOW BERYLLIUM PEL

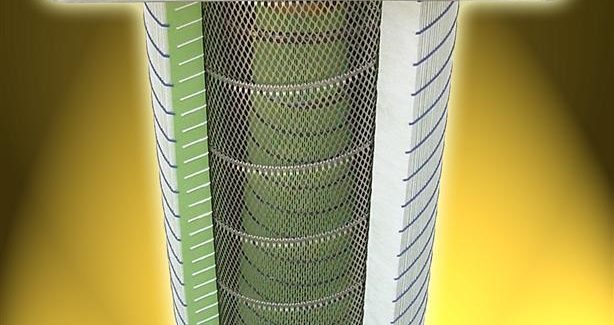

A dust collector is an accepted and proven engineering control to help metalworking facilities reduce operator exposure to hazardous dusts. It filters contaminants to make shops and plants safer and healthier. A dry media dust collection system containing high efficiency cartridge filters along with high efficiency secondary filters are the best control for respirable particulates.

Primary filter media is selected based on the dust particle size and distribution. A higher efficiency media will be required to comply with OSHA’s beryllium standard of a PEL of 0.2 micrograms per cubic meter of air. Metalworking processes that produce light loading dry dust can utilize PTFE membrane coated filter media (EN filter class E10/85 percent on MPPS) for the primary filters. Processes that produce heavier loading dusts can also use a high efficiency nanofiber media (EN filter class F9). Secondary filters are recommended for use downstream of the primary filtration system utilizing HEPA filters (EN filter class H13). They prevent hazardous dusts from discharging to the atmosphere, and can be configured to prevent return air ducting contamination and the associated cost to clean hazardous dust leakage.

DUST AND FUME CONTROL FOR WELDING OPERATIONS

A well-designed cartridge system will filter welding fumes and other hazardous contaminants. These systems use self-cleaning mechanisms that pulse dirt off the filters, allowing units to run longer between filter change-outs. There are three general types of dust and fume collection systems used to clean up welding processes:

- Source capture typically utilizes a flexible source capture arm, an enclosure around the operation, and negative air pressure to contain the dust. Source capture requires less air, and is safer and more efficient with just about any type of wet or dry collection system.

- Canopy hoods are often used if the operation’s footprint area is a medium size such as 12 ft x 20 ft or less. Curtains or hard walls may be added to the sides to create a booth or enclosure, but it is dependent on workspace requirements and available space.

- Ambient systems filter all of the air in the shop using a central system or multiple smaller collectors. It’s important to note that ambient systems are not a viable option for hazardous dust control because they do not prevent the dust from becoming airborne and dispersed throughout the workspace.

COLLECTING AIRBORNE BERYLLIUM MIST

Workers can also be exposed through machining fluid mist in operations where beryllium is present. When designing equipment for mist removal, the best solution is a high efficiency mist collector designed to remove wet coolants using two stages of long-life coarse and fine filter demisters followed by a HEPA secondary filter.

https://youtu.be/BLi42ITEIA4

ASSESSING COMPLIANCE

OSHA states that if airborne beryllium dust, fume or mist is released into workplace air, employers must assess the airborne exposure of each employee using one of two methods:

- Performance option. Employers assess the eight-hour TWA exposure and the 15-minute short-term exposure for each employee on the basis of air monitoring data and objective data sufficient to accurately characterize beryllium exposure.

- Scheduled monitoring option. Employers perform initial monitoring to assess the 8-hour TWA exposure for each employee on the basis of one or more personal breathing zone air samples that reflect the airborne exposure of employees on each shift, for each job classification, and in each work area.

PREVENTION IS THE BEST STRATEGY

Job shops and other metalworking facilities affected by the standard must comply with most of the requirements by March 12, 2018, which is one year from the original effective date. They have two years to provide any required change rooms and showers and three years to implement engineering controls. The best strategy to protect workers from the devastating pulmonary diseases associated with beryllium exposure is using proven engineering controls like dust, mist and fume collectors.

References

- OSHA national news release, https://www.osha.gov/news/newsreleases/national/03012017.

- OSHA Final Rule to Protect Workers from Beryllium Exposure, https://www.osha.gov/berylliumrule/index.html.

- OSHA Final Rule: Occupational Exposure to Beryllium, https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=FEDERAL_REGISTER&p_id=27623.

- OSHA Beryllium Rulemaking, https://www.osha.gov/dsg/beryllium/rulemaking.html.

- OSHA Fact Sheet: Protecting Workers from Exposure to Beryllium and Beryllium Compounds: Final Rule Overview, https://www.osha.gov/Publications/OSHA3821.pdf.

- OSHA Safety & Health: Beryllium, https://www.osha.gov/SLTC/beryllium/index.html.

- OSHA Beryllium Rule General Industry Standard, https://www.osha.gov/berylliumrule/GeneralIndustry_Beryllium_Regulatory_text.pdf.

- OSHA: Medical Surveillance for Beryllium-Exposed Workers, https://www.osha.gov/Publications/OSHA3822.pdf.

- American Welding Society: Welding Copper and Copper Alloys, https://www.copper.org/publications/pub_list/pdf/a1050.pdf.

- Materion Tech Briefs: Welding Copper Beryllium, https://materion.com/-/media/files/pdfs/alloy/tech-briefs/at0014-0311—tech-briefs—welding-copper-beryllium.pdf.