Advanced Metrology Systems for Metal Fabrication

Hexagon Manufacturing Intelligence offers TubeShaper software specifically for inspection using their ROMER Absolute Arm, and also HxGN SMART Quality, a remotely accessible web-based platform software that harnesses the quality data stream across multiple phases of manufacturing.

Posted: September 12, 2017

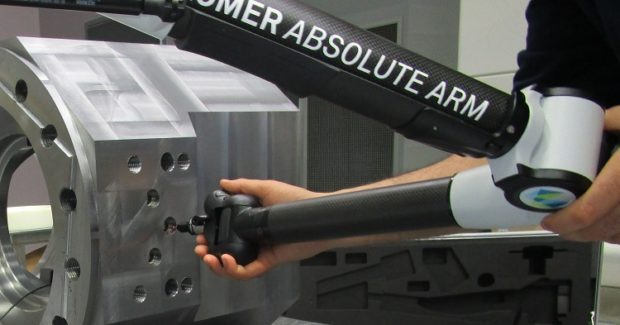

In Booth A1032, Hexagon Manufacturing Intelligence (North Kingstown, RI) will feature TubeShaper software. Developed specifically for their ROMER Absolute Arm in close collaboration with some of the world’s leading tube producers, this software is used for the measurement, gauging and manufacture of tubes. The easy-to-handle ROMER Absolute Arm uses non-contact tube probes, available in six different sizes, to measure tube length and bend angles as XYZ, LRA or YBC values, while standard touch probes ensure that full tube assemblies – including any welded fixtures like brackets or hangers – can be measured. Drawing upon 30 years of expertise in the tube industry, this system combines the best features of its predecessors with cutting-edge technology to create an advanced, intuitive software program that can even be used by novices with little experience in tube, pipe or bent-wire measurement.

Designed to maximize production efficiency and reduce scrap, TubeShaper offers direct connections to CNC tube bending machines, automatic measurement plan creation and direct import of CAD models. Its interface enables the operator to fully harness the measurement potential of the ROMER Absolute Arm for all tube inspection applications. The calculation and application of spring-back values, bend corrections, reverse engineering and part-to-CAD tube inspection are easier and faster than ever before. Using this software, measurement plans are created automatically during first-part inspection or can be entirely defined and set up prior to measurement, making batch measurements faster while guaranteeing repeatability. Full tube assemblies, including welded brackets, hangers and flanges, can also be checked thanks to TubeShaper’s advanced CAD engine and the tactile probe of the ROMER Absolute Arm. This tube measurement software is a complete package for quality managers and shop floor users.

Also on display will be HxGN SMART Quality, a powerful online quality lifecycle management software platform that harnesses the quality data stream across multiple phases of manufacturing, providing knowledge through comprehensive statistical analysis, visualization and workflow management. HxGN SMART Quality enables real-time process improvements that increase the competitiveness of manufacturing businesses. This remotely accessible web-based platform enables users at various organizational levels to manage quality requirements along the product lifecycle in virtually real-time. Companies can collect and store quality data from any number of devices across multiple factories in one database. Users can analyze, visualize and report data using a manageable, user-friendly dashboard format. Resources such as quality equipment can also be managed, which can help improve process workflows and organize operational tasks.

HxGN SMART Quality is scalable to fit any organizational structure or facility network and is embedded in the user’s IT infrastructure. Based on a highly configurable standard toolset, this system can be tailored to the specific requirements of most manufacturers without the need for extensive development or costly customization, saving both time and money. Whether installed on a single production line, throughout a manufacturing plant or across multiple sites of an enterprise, this web-based platform’s tools for connectivity, actionable statistics and resource management enable businesses to take control of their data and work smarter.

Also on display will be the most accurate ROMER Absolute Arm to date: The 77 series is designed to provide absolute accuracy for high-end 3D measurement applications. This advanced PCMM achieves nearly a 20 percent improvement in scanning accuracy, a 15 percent improvement in touch-probe measurement accuracy over the popular 75 Series, and is available in five sizes from 2.5 m to 4.5 m measuring volumes. The 77 series combines its high precision measurement advances with the proven technology of the ROMER Absolute Arm while retaining the arm’s user-friendly nature. The ROMER Absolute Arm is the only PCMM in the industry that can be switched on and used immediately without warm-up or referencing. Probe changes can also be made without recalibration to maximize flexibility on the job. Acoustic and haptic operator feedback facilitate use in harsh shop floor environments. The standard, versatile 3000 N magnetic base offers mounting options for all kinds of applications and part sizes.

Like the 73 Series and 75 Series arms, 77 Series arms are compatible with all Hexagon Manufacturing Intelligence laser scanners, including their RS3 and RS4 integrated scanners and their HP-L-20.8 and HP-L-8.9 external units. All of these arms are available in 6-axis and 7-axis configurations. The 6-axis models are ideal for touch-probe measurement, while the 7-axis design is well suited for high-speed laser scanning. Like the 73 Series and 75 Series arms, 77 Series arms are compatible with all Hexagon Manufacturing Intelligence laser scanners, including their RS3 and RS4 integrated scanners and their HP-L-20.8 and HP-L-8.9 external units. All of these arms are available in 6-axis and 7-axis configurations. The 6-axis models are ideal for touch-probe measurement, while the 7-axis design is well suited for high-speed laser scanning.

https://www.youtube.com/watch?v=35zyLox92Pk

Hexagon Manufacturing Intelligence, 250Circuit Drive, North Kingstown, RI 02852, 401-886-2000, www.hexagonmi.com.