Coil Fed Laser Cutting with Unmatched Flexibility

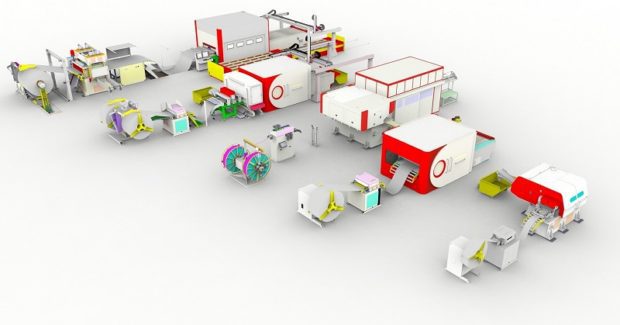

The LINACUT coil fed laser cutting system from Dimeco Coil Technologies combines the flexibility of laser cutting and turret punching together with the performance of coil fed processes with a fully automatic part sorting system for non-stop processing of coils.

Posted: September 11, 2017

In Booth A3591, the LINACUT® coil fed laser cutting system from Dimeco Coil Technologies, Inc. (Chicago, IL) combines the unmatched flexibility of laser cutting and turret punching together with the performance of coil fed processes. It is the perfect complementary equipment to existing flat-bed laser and CNC turret punching machines. The system uses an on-purpose coil handling line for coils up to 25 tons (55,000 lb) and coil widths up to 2,000 mm (80 in). One coil of 1 mm (19 ga) thick material is about 2,000 m (6,500 ft) of material that can be processed non-stop and with a very limited scrap level. The LINACUT continuous laser cutting module cuts sheet metal up to 4 mm (8 ga) thick and the line has a fully automatic part sorting system. Part length has no other limit than the available space inside the shop.

Dimeco Coil Technologies, Inc., 35 East Wacker Drive, Suite 670, Chicago, IL 60601-2114, 312-868-3916, www.dimeco.com.