Deburring, Edge-Rounding and Leveling Systems Reduce Operating Costs Downstream

The EdgeBreaker 4000 Plus from ARKU removes burrs/slag to create a clean, even surface and sides on parts up to 3.3 in thick. Their FlatMaster 55 precision leveler quickly delivers leveled and stress-relieved parts and sheets that have been punched or cut by laser, flame and oxyfuel.

Posted: September 27, 2017

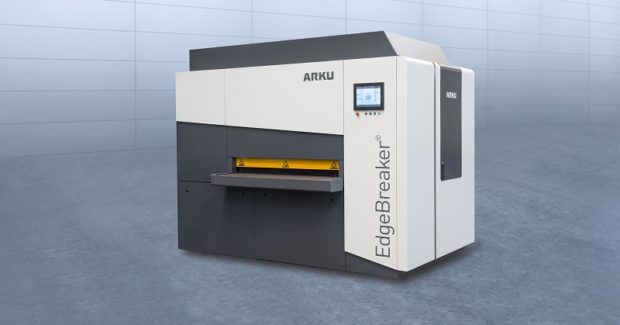

In Booth A2862, ARKU Coil Systems Inc. (Cincinnati, OH) will feature the powerful and reliable EdgeBreaker® 4000 Plus deburring and edge-rounding machine. Whether it is aluminum, steel, titanium, stainless steel or copper, the oscillating drum in the EdgeBreaker removes undesired burrs/slag on various materials to create a clean, even surface. This machine is capable of processing parts up to 3.3 in thick and is ideal for processing flame-, laser-, plasma- and oxyfuel-cut parts. The edge-rounding unit runs in a transverse direction to provide the most possible contact with the material. The unit is equipped with edge-rounding blocks that round the edges on both sides and has the option to exchange these blocks for grinding blocks on either the top or bottom side for additional removal of burrs. In addition, the blocks’ vibration-free movement guarantees precise results. The edge-rounding/grinding blocks can be replaced quickly by using a patented click system.

The calibration unit of the edge-rounding/grinding blocks measures and automatically compensates for the wear on the blocks. This ensures optimal processing results, regardless of the wear on the consumables. The machine is also capable of storing processing data of parts whose parameters were previously entered into the control system. This allows the operator to process a variety of materials by being able to simply select the saved part parameters.

https://youtu.be/YikxPfOMJ-c

Also on display will be the FlatMaster® 55 precision leveler that delivers – in only a matter of minutes – leveled and stress-relieved parts and sheets that have been punched or cut by laser, flame and oxyfuel. Leveling with the FlatMaster is a quick and simple process, especially compared to other flattening methods. Leveling allows for subsequent processes, such as welding or bending, to be more efficient and consistent. The integrated leveling gap control and the quick-change system for the leveling rollers make the FlatMaster very precise and maintenance-friendly. Flatness defects and residual stress in sheets or parts are leveled easily and efficiently. The intuitive touch screen control panel is easy and user friendly for operators. The machine is also capable of storing processing data of parts whose parameters were previously entered to allow the user to process the same material again without having to manually reenter all the parameters. Additionally, the overload protection ensures complete protection against operator error for the mechanical interior part of the machine.

ARKU Coil Systems Inc., 11405 Grooms Road, Cincinnati, OH 45242, 513-985-0500, www.arku.com.