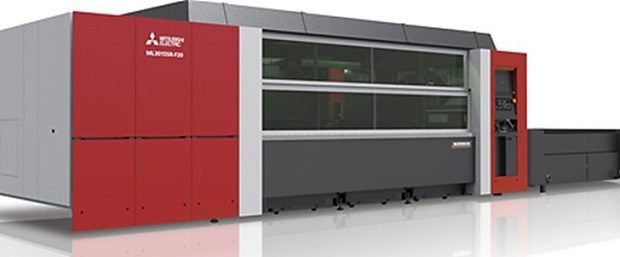

Economical Entry Level Fiber Laser Cutting System

The Mitsubishi SR-F two-dimensional fiber laser processing system from MC Machinery features a 3 m by 1.5 m footprint with 2 kW or 3 kW power and standard fiber laser resonator, processing head and safety cover.

Posted: September 28, 2017

In Booth A2619, MC Machinery Systems, Inc. (Wood Dale, IL) will demonstrate their all-new SR-F series fiber laser cutting system from Mitsubishi that features a 3 m by 1.5 m footprint with many of the features and options that are popular in the bestselling eX-F laser. The SR-F laser is available with 2 kW and 3 kW power. This economical entry level machine offers the superior advantages of a two-dimensional fiber laser processing system that comes standard with a fiber laser resonator, a processing head and a safety cover. It also includes the sophisticated Mitsubishi 700 series control with 64-bit NC and a 15 in touch screen. Other standard features of the SR-F include:

- Motion Cut – features the beam on/off time and axial movement simultaneously to eliminate the need for the axes to stop.

- Eco Mode – reduces cost during standby by up to 70 percent.

- Power Control System – provides power stability of ±1 percent.

- Automatic Focusing – allows for easy and consistent focusing.

- Magnetic Damage Reduction Function – protects the head and eliminates the need f or nozzle centering in the event of a crash.

- MC Remote 360 – provides real-time data to help increase productivity, improve efficiency, and reduce down time

Fiber laser technology dopes the optical fiber of the active gain medium. Since the light is already in a fiber, this allows a flexible path for delivering to a movable focusing element, such as the processing head. The technology eliminates bend mirrors and effectively eliminates the need for beam adjustment and alignment, improving consistency. This is important for production jobs including laser cutting, welding and fold forming.

MC Machinery Systems, Inc., 1500 Michael Drive, Wood Dale, IL 60191, 630-616-5920, www.mcmachinery.com.