FABTECH 2017: Forming & Fabricating (Part Two)

The 2017 edition of FABTECH is on track to be one of the largest metal fabrication events ever at McCormick Place in Chicago, and our special coverage provides technical reviews of some of the metal forming and fabricating machinery, tooling, systems and accessories that will be exhibited to help you navigate the show floor and manage your time while you’re there.

Posted: September 20, 2017

FABTECH 2017 is North America’s largest collaboration of technology, equipment and knowledge in the metal forming, fabricating, welding and finishing industry. The event takes place November 6-9 and will occupy over 750,000 sq ft in the McCormick Center in Chicago, where more than 1,700 exhibitors and 50,000 attendees will have full access to special events, presentations, educational sessions and live demonstrations of the latest technology and integrated solutions, along with one-on-one exchanges with exhibitors and networking with industry leaders. There will also be opportunities to attend keynote presentations, a state of the industry outlook, discussions on key industry issues that influence manufacturing, and more. You don’t want to miss this:

How to Dramatically Reduce Fitup and Welding Costs in Heavy Fabrication

FitPerfect systems from HGG Profiling Equipment use unique 3D steel profile cutting capabilities to combine plasma and oxyfuel processes and minimize grinding time, including a wide range of innovative and high quality CNC cutting machines, custom machinery and associated equipment for cutting steel beams, pipes and tubing.

Advanced Metrology Systems for Metal Fabrication

Hexagon Manufacturing Intelligence offers TubeShaper software specifically for inspection using their ROMER Absolute Arm, and also HxGN SMART Quality, a remotely accessible web-based platform software that harnesses the quality data stream across multiple phases of manufacturing.

Lightweight Ultra-Low Profile Mag Drill for Confined Spaces

The compact HMD130 Portable Magnetic Drill from Hougen features a bayonet-style twist and lock cutter mounting system and a height of only 6-11/16 in that is small enough to drill in confined spaces where even handheld electric drills can’t go.

Magnetic Sheet Separation and Material Handling for Stamping, Blanking and Other Fabrication Operations

Magnetic sheet separation fanners from Industrial Magnetics are ideal for automotive, office furniture, appliance, stamping and fabrication operations, as well as safe and efficient mid-stack changeover of blanking lines.

Smart Factory Technology for Next Generation Sheet Metalworking

For high precision and high part output, flexible Industry 4.0-ready systems from LVD Strippit include the 8 kW Electra 3015 fiber laser, the TL 2665-FL tube laser cutting machine, the ToolCell automated tool changing press brake, the Dyna-Press electric-drive press brake, and the Strippit PX-1530 punch press.

Abrasive Waterjets that Redefine Value

Capable of cutting virtually any material, OMAX systems include the 80X JetMachining Center with a Tilt-A-Jet cutting head, Rotary Axis and a 50 hp EnduroMAX pump; the MAXIEM 1530 with an A-Jet cutting head, Rapid Water Level Control, and 40 hp pump; and the GlobalMAX 1508 with 20 hp pump.

Band Saw Blades for Bundled and Structural Sawing and More

Simonds Saw offers IC Enduro blades for bundled and structural sawing, and BroadBand blades for a myriad of fabricating jobs.

High Power Pumps Increase Waterjet Productivity and Reduce Abrasive Costs

PRO-III 90,000 psi pumps with topworks from KMT Waterjet Systems have a patented seal design canister for protecting seals, and their compact TRILINE 55,000 psi pump with direct drive technology is ideal for job shops performing conventional shapecutting and more.

Deslag Line for Metal Service Centers

The Deslag Line from LISSMAC uses Power Pin Belts on top and bottom that chip away the slag formed from plasma or oxy-fuel cutting systems, then two grinding belts on the top and bottom complete a final grind of any slag left on the part, and two sand block belts on the top and bottom round the edges on the part.

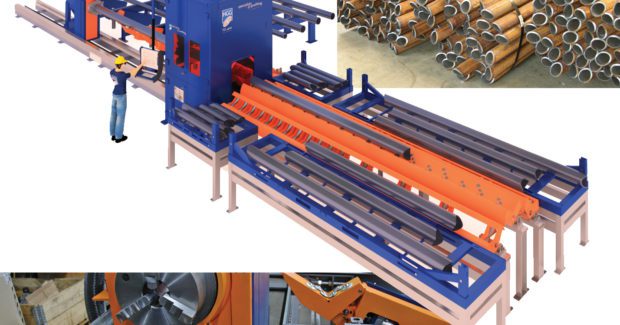

Automated Sawing Systems and Versatile Ironworkers

For the most effective fabrication operations, Scotchman offers a complete line of hydraulic ironworkers, circular cold saws, band saws, tube and pipe notcher/grinders, manual measuring systems and programmable feed and stop system.

Innovative, Ultra-Fast Tube Cutting Software

Fully integrated inside SOLIDWORKS and capable of programming all tube shapes and sizes, SigmaTUBE X1 automated tube cutting CAD/CAM software from SigmaTEK is a complete tube cutting system for 4-axis, 5-axis and 6-axis cutting machines that automatically processes and programs entire assemblies.

Innovative Plasma Cutting Technology Breaks Multi-Process Barriers

The Plasma Nova system from Soitaab combines plasma cutting with a straight or bevel head, oxy-fuel cutting, various kinds of marking, variable size drilling and tapping, and even 3-dimensional shapes like pipe cutting by using heavy duty Dual Side Drives and Digital Controllers to maintain excellent positioning accuracy and cut tolerances across the entire working area.