FABTECH 2017: Welding (Part Two)

The 2017 edition of FABTECH is on track to be one of the largest welding events ever at McCormick Place in Chicago, and our special coverage provides technical reviews of some of the welding systems and accessories that will be exhibited to help you navigate the show floor and manage your time while you’re there.

Posted: September 22, 2017

FABTECH 2017 is North America’s largest collaboration of technology, equipment and knowledge in the metal forming, fabricating, welding and finishing industry. The event takes place November 6-9 and will occupy over 750,000 sq ft in the McCormick Center in Chicago, where more than 1,700 exhibitors and 50,000 attendees will have full access to special events, presentations, educational sessions and live demonstrations of the latest technology and integrated solutions, along with one-on-one exchanges with exhibitors and networking with industry leaders. There will also be opportunities to attend keynote presentations, a state of the industry outlook, discussions on key industry issues that influence manufacturing, and more. You don’t want to miss this:

Shield Workers from Fumes, Sparks and Flying Debris

The Defender high speed, high cycle automated door from Rite-Hite Machine Guarding separates machine operators and manufacturing processes while containing fumes, sparks, smoke, mist, flying debris, excess noise and other common operating process by-products.

Welding Wires that Help Avoid Downtime and Operate More Efficiently

NS Plus copper-coated carbon steel, NS CopperFree carbon steel, Satin Glide stainless steel, Alumi Glide aluminum and Tru Core flux core and metal core welding wires from National Standard have excellent feedability and reduce smoke and spatter to increase welding productivity.

Next-Generation Plasma Beveling Technology Increases Productivity with Minimal Operator Intervention

The DMX Automated Plasma Beveller from ESAB uses SmartBevel Technology for easier programming and accurate cutting of a full range of weld preparations, including V, Y, X, and K bevels, with cut angles up to 45 deg on materials up to 50 mm.

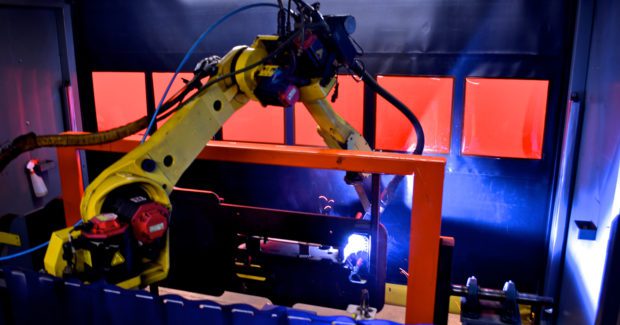

Automation Systems for Welding, Cutting, Additive Manufacturing and More

Compact, high performing and reliable Fiber (FF) Laser oscillators from FANUC use direct, high speed control through a robot equipped with LaserTool application software for high precision in a wide range of cutting, welding and additive manufacturing tasks.

How Tungsten Electrode Grinding Helps Improve TIG Weld Quality

The Huntingdon Fusion TEG-1000 Tungsten Electrode Grinder from COB Industries sharpens electrodes correctly for perfectly ground and polished tips that enable consistent, repeatable arc performance and improved TIG welding quality.

New Class of High Definition Plasma Cutting on Mild Steel, Stainless, and Aluminum

The XPR300 300 amp plasma system from Hypertherm can use X-Definition plasma technology to deliver ISO-9013 Range 2 cut quality on thin mild steel and extended ISO Range 3 cuts on thicker metals, including squarer cut edges, markedly less angularity, and excellent surface finish on non-ferrous metals like aluminum and stainless steel.

Remote Technology for Less Walking, More Welding and Improved Productivity, Safety and Quality

Take a closer look at how advanced welding and safety equipment from Miller Electric increases productivity in manufacturing, fabrication and construction operations.

First MIG Welding System in the U.S. for Collaborative Robots

Ideal for low volume/high mix fabrication shops, the Collaborative Robot Welding Package developed by ARC Specialties and Universal Robots is a cobot-assisted, interactive welding system that can be deployed easily and flexibly in existing manual welding booths, eliminating the need for costly new robotic cells.

Reduce Slag Buildup with Long-Lasting Protection for Laser and Plasma Cutting Tables

E-Weld Plasma from Walter Surface Technologies is a ceramic, water-based, anti-spatter solution that is applied to laser and plasma cutting tables to reduce slag build-up and provide long-lasting protection – even under extreme heat – by inhibiting the adherence of slag.

Abrasives for Weld Preparation, Cutting, Grinding and Cleaning

The latest abrasives, resin fiber discs, flap discs and more from Weiler Abrasives provide exceptional performance in weld preparation and cleaning of difficult to cut and grind materials, like aluminum and stainless steel.

Robotic Workcells for Low to Medium Runs of Small, Medium and Large Parts

The modular ArcWorld 2000 workcell from Yaskawa America is specifically designed for the robotic welding of large parts, while the ArcWorld 200 and ArcWorld 500 welding systems are versatile workhorses for small- to medium-sized parts or medium-volume production runs.

How to Answer the Most Aggressive Stock Removal and Blending Challenges

Extra heavy-duty Norton Rapid Prep XHD Coarse and Medium Discs from Norton | Saint-Gobain Abrasives significantly save labor and consumable costs by reducing application steps and removing weld lines, weld splatter, weld discoloration and blend surfaces in a single step.