High Performance, Large Format Laser Cutting and Engraving Operations

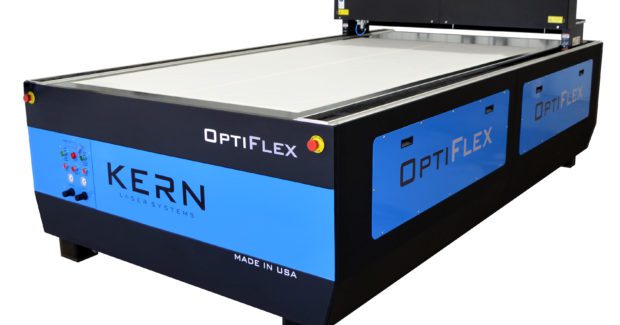

The next generation OptiFlex large format laser cutting and engraving system from Kern Laser uses a new HyperDual motion package with a rack-and-pinion gear system at each side of the laser system and dual Y-axis servo motors for cut acceleration rates up to three times faster and a 100 percent increase in top-end vector speed.

Posted: September 28, 2017

In Booth A4280, Kern Laser Systems (Wadena, MN) will introduce their next generation OptiFlex laser system, a redesigned large format system equipped with their new HyperDual motion package. This improved motion package features a rack-and-pinion gear system at each side of the laser system, with dual Y-axis servo motors. Cut acceleration rates are up to three times faster, with a 100 percent increase in top-end vector speed. The X-axis has been upgraded with twin linear rails and a thicker steel reinforced belt. The OptiFlex system sets the standard for a high performance, large format laser cutting and engraving system.

Also being debuted will be the FiberCELL laser cutting system, a compact sheet metal fabricating system that is capable of cutting a variety of metals. A Class 1 safety enclosure allows this system to be placed in high traffic areas, such as busy factory floors and university classrooms. Gull wing doors at the front and back, as well as side sliding windows, make part loading and removal an easy task. Advanced CAD software is available on the FiberCELL that is capable of creating automatic lead-ins, part nesting, chain cutting and cost modeling reports. For users looking to modernize their shop equipment, the FiberCELL offers the perfect blend of production and safety.

Kern Laser Systems, 1501 Industrial Drive, Wadena, MN 56482-2500, 888-660-2755, info@kernlasers.com, www.kernlasers.com.