No More Rework or Cleaning of Parts Due to Corrosion

Clear Pak BIO corrosion inhibitor (VCI) packaging film from Daubert Cromwell is flexible, puncture and tear resistant and uses proprietary, plant-based corrosion inhibitor chemistry to protect valuable metal components during storage and shipment.

Posted: September 25, 2017

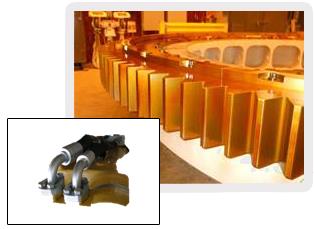

In Booth A4917, Daubert Cromwell, LLC (Alsip, IL) introduces their Clear Pak® BIO corrosion inhibitor (VCI) packaging film, an effective and environmentally safe packaging film for the metalworking community. Clear Pak BIO uses proprietary, plant-based corrosion inhibitor chemistry proven effective for protecting valuable metal components during storage and shipment. Independent lab testing shows that the transparent, heat-sealable, recyclable film excels in rigorous testing to international standards, including German product health and safety regulation TRGS 615. Clear Pak BIO is designed to prevent corrosion on ferrous metals by using advanced VCI chemistry that is derived from plant extracts that are nitrite-free, amine-free, and non-toxic. The flexible, puncture and tear resistant film is tinted a unique shade of purple to identify it as a quality product of Daubert Cromwell. Clear Pak BIO is compatible with their entire line of VCI packaging papers, films, foams, emitters and devices, and rust preventive liquids.

Metal fabricators often need economical, effective rust preventive liquid coatings to protect metal surfaces between factory and delivery. Without adequate protection, valuable metals can become vulnerable to rust and the resulting expensive rework. To help keep precision machined parts corrosion-free in harsh outdoor environments, Daubert Cromwell has developed a series of Transit Coatings specifically for metals stored and shipped outdoors. New Nox-Rust 3100 liquids protect metal and most painted surfaces during domestic and international shipment. When properly applied, they will prevent damage from sea water, acid rain, insects, bird droppings, smoke, pollution, dirt, and debris. These Transit Coatings include:

- Nox-Rust 3100 – Easy-to-use liquid protects metals stored outside for over five years. In salt fog testing, the most rigorous ASTM standard for measuring the effectiveness of corrosion protection, Nox-Rust 3100 outlasted the competition in salt fog and humidity testing. This is the best choice for protecting equipment and machinery during domestic and overseas shipments.

- Nox-Rust 3100G – New Nox-Rust 3100G has the same excellent corrosion protection properties as Nox-Rust 3100, but in a thicker consistency that clings to vertical surfaces. It adheres to the metal to provide an even layer of protection on large, heavy, or hard-to-reach metal parts. Apply by spray or brush.

Technical representatives will demonstrate these and the entire line of rust preventive liquids for metalworking applications during the show.

Corrosion inhibitor (VCI) film bags come in sizes to fit the largest parts bins, crates and corrugated boxes that are used in metalworking operations to effectively protect metal surfaces against corrosion during storage and shipping. They keep properly packaged metal clean and dry throughout the production process. The film acts as a barrier to moisture, dirt, dust and corrosion-causing contaminates. When parts are removed from the VCI packaging, they are ready to use without further rework or cleaning. Daubert Cromwell will demonstrate the proper use of VCI films and their entire range of anti-rust liners, shrouds, covers and other packaging during the show.

Daubert Cromwell, LLC, 12701 South Ridgeway Avenue, Alsip, IL 60803, 708-293-7750, Fax: 708-293-7765, info@daubertcromwell.com, www.daubertcromwell.com.