Press Brake and Turret Punch Tooling Increases Efficiency, Reduces Errors and Costs

To gain efficiency, reduce errors and lower operating costs, Wilson Tool offers the Express Crowning System and rotary bend tooling for press brakes, iSeries AITS thick turret tooling and the QuickTap tapping tool for turret presses, and the fully automated XSharp grinder.

Posted: September 19, 2017

In Booth A2831, Wilson Tool International® (White Bear Lake, MN) will showcase five products that are available to assist fabricators in gaining efficiency, reducing errors and lowering costs in their operations. Their Express Crowning™ System is designed to help control deflection on the press brake by allowing for fine-tuning the curve of press brake bends so that parts over 4 ft long result in less problematic deflection. This system allows the user to adjust crowning to a macro and micro degree so that compensation is catered to the nuances built into the machine. Manual or electric power crowns the lower beam and dies are secured with manual or hydraulic power.

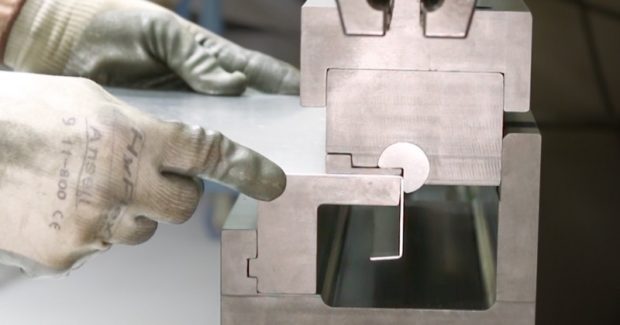

Also on display is their new iSeries™ AITS® line of thick turret tooling that is fully compatible with the Amada ID Tooling System (AITS) tool management system. Each compatible tool is laser-marked with a data matrix code for easy system integration and HPX and HP2 options have a mechanically fastened guide retention feature to keep tool securely assembled during loading. The iSeries offers shorter lead times, competitive pricing and premium quality tooling. Also on display is their rotary bend tooling, an excellent option for reducing excess labor costs and ensuring operator safety by utilizing a rotating cam that overbends material to make more precise bends while compensating for springback. This press brake tool helps reduce the need for additional operators when bending large sheets because the rotating cam creates less movement of the sheet. Rotary bend tooling also reduces the tonnage needed to make bends and therefore can extend the life of the machine.

Tapping is a common application that’s best done in the punch press to prevent time-consuming secondary operations. On display will be their QuickTap™ tapping tool, the fastest and most reliable tapping tool on the market, capable of tapping up to 200 holes per minute. Also on display will be their fully automated XSharp™ grinder that is suitable for all tooling styles and provides highly stable bearing properties to ensure a high level of precision and an excellent surface finish on sharpened tools. It is simple to program and use with automatic height detection and wheel wear compensation and a user-friendly touch screen controller.

https://youtu.be/sggvDxQyVr0

Wilson Tool International, 12912 Farnham Avenue, White Bear Lake, MN 55110, 866-752-6531, sales@wilsontool.com, www.wilsontool.com.