Shield Workers from Fumes, Sparks and Flying Debris

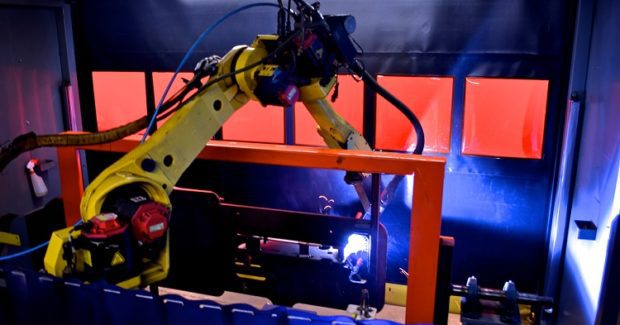

The Defender high speed, high cycle automated door from Rite-Hite Machine Guarding separates machine operators and manufacturing processes while containing fumes, sparks, smoke, mist, flying debris, excess noise and other common operating process by-products.

Posted: September 22, 2017

In Booth B31064, Rite-Hite Machine Guarding (Milwaukee, WI) introduces the industry’s most sophisticated automated barrier door, the Defender. Designed to guard machinery, contain processes and protect employees from robotic/machine movement zones, this new door boasts patent-pending upgrades to its non-contact safety switch configuration, control systems and interlocking capabilities. It also features a new, more resilient curtain material that resists a wider array of application driven hazards and offers optional variable frequency drive to control curtain speed. In addition, it utilizes new quick-disconnect cables, which allow for easier installation and integration than comparable barrier doors.

The Defender is a high speed, high cycle automated door that separates machine operators and manufacturing processes. It is an ideal safeguarding device for robotic welding cells, material handling, automated assembly, palletizing/packaging machinery and other applications that require electronic safe guarding devices. It also contains fumes, sparks, smoke, mist, flying debris, excess noise and other common manufacturing process by-products. Additionally, its roll-up design leaves a minimal footprint into the typically crowded manufacturing cell. The Defender automated barrier door features a host of innovations, including:

- PLe hold-down mechanism that locks the door in “down” position to allow for machine “de-energizing” time (necessitated by issues such as roll inertia in the paper industry).

- Redesigned rotary cam limit switch, encoder positioning and variable frequency drive to control the curtain’s operating speed and position, dramatically improving the adjustability of door position, speed and control.

- Non-contact interlock switches manufactured by Jokab, Pilz, Schmersal and Allen Bradley that provide up to PLe specifications per EN ISO 13849-1 when integrated properly.

- Designed with EN 10218-2 specifications in mind.

“This is the most feature-rich automated barrier door we’ve ever manufactured,” said Eric Esson, the global marketing manager of Rite-Hite Machine Guarding. “It takes into account all aspects of the new regulations and the demands of the industry as a whole. Given the new OSHA (ISO 13849-1) and RIA (EN 10218-1) regulations, it should appeal to a wider variety of industries than any of our previous automatic barrier doors, including new manufacturing processes and industrial applications including conveyors, industrial elevators and palletizing applications. Additionally, the Defender is a great alternative to light curtains and area scanners, going the extra step to contain the process.”

Also on display will be the Vertiguard Automated Barrier Panel with several upgrades that make it an even better option for industrial facility managers looking to increase safety and productivity in their plants. The Vertiguard is a unique bottom-up pneumatic panel that provides physical separation between machine operators and manufacturing processes. An alternative to light curtains or area scanners, it is ideal for small interaction points with single or double robotic cells, part assembly, and conveyor openings. The Vertiguard reduces the footprint of the guarding system as compared to light curtains or scanners and provides workers with better protection from application-driven hazards. This vertically rising system also allows for overhead crane loading and its simple pneumatic operation helps increase productivity. The low-profile design also helps prevent back injuries, since it requires minimal reach-in to load parts.

The most noticeable difference in the new Vertiguard is its standard size, which has been increased significantly, to 110 in wide and 96 in tall (from 72 in wide and 86 in tall). Other upgrades include:

- Improved finger guard using a 40 oz FR vinyl sewn-in loop design to eliminate pinch point.

- New brand cylinder and flange mount with center support.

- Improved sliding panel design for smoother operation.

- More options, including eliminating the toe gap to allow for lower stored panel heights.

- Improved interlock switch brackets and additional switch options, including AB and Jakob Safety.

- Galvanized steel back panel and cylinder cover.

- Availability of 3D modeling for easy insertion into project drawings.

- Improved pneumatic hose and fitting quality.

- Photo-eye strip option to prevent door movement when obstructions are sensed.

The Vertiguard is manufactured under ISO 9001 specifications and comes fully assembled with a one-year warranty. Equipped with optional Cat. 4, PLe, SIL 3 switches and controls (per EN 954.1, EN ISO 13849-1 and EN 62061 specifications), it is an ideal safeguarding device in robotic welding cells, materials handling, automated assembly, palletizing/packaging machinery and other applications that require both electronic safeguarding devices and physical separation.

Rite-Hite Corporation, 8900 North Arbon Drive, Milwaukee, WI 53223, 414-355-2600, Fax: 414-355-9248, www.ritehite.com.