Weld Dissimilar Materials and Eliminate Post-Weld Inspection Processing

The automated SpinMeld friction spin welding system from Coldwater Machine is a very fast solid-state joining technology for steels, aluminum, cast or sintered metals, carbide materials, magnesium, nickel, molybdenum, and other exotic materials that normally may not be welded using other methods.

Posted: September 11, 2017

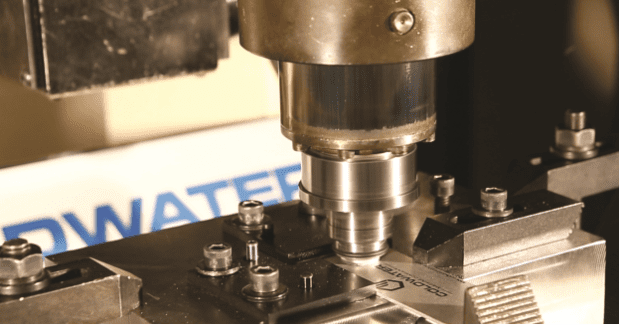

Lincoln Electric Automation, Coldwater‘s (Coldwater, OH) automated SpinMeld friction spin welding (FSW) system, a solid-state joining technology for steels, aluminum, cast or sintered metals, carbide materials, magnesium, nickel, molybdenum, and other exotic materials that normally may not be welded using other methods. The SpinMeld process is servo-controlled with a high speed spindle, bringing critical parameters under control with in-process monitoring to improve part quality and eliminate post weld inspection. These systems are available with automatic parts handling and inspection, or as stand-alone units or may be integrated into a turnkey solution. Each machine is designed to fit the individual application with parameters such as rotational speed, cycle time, and forging force fully customizable.

SpinMeld can lower the cost to manufacture a wide range of applications where a high strength, non-porous joint is needed. Because the process is very fast, with weld times typically under three seconds, it is often possible to replace other processes including arc, resistance and projection welding with better results. The chief advantage of this system is the ability to produce a superior joint on a wide variety of materials without altering the crystalline structure of the base materials, so that the joint strength is very high and the heat affect zone small. The system is well-suited for bar stock and tubes, rods, cylinders, fasteners, studs, nuts and fittings on various parts, as well as drills rods and hand tools with carbide inserts, heat sinks, air bag inflators, electrodes and virtually any shafted components.

Given this wide variety of potential applications, Lincoln Electric Automation, Coldwater has a friction welding lab to support product development and weld studies to allow users to investigate new approaches to joining materials. Getting started means sending the company a few sample pieces that will be friction welded to confirm the feasibility of joining the materials.