When Repair Isn’t an Option

GTI examines the three main factors that must be considered for spindle replacement in critical high frequency ID grinding operations of aerospace and automotive parts.

Posted: September 28, 2017

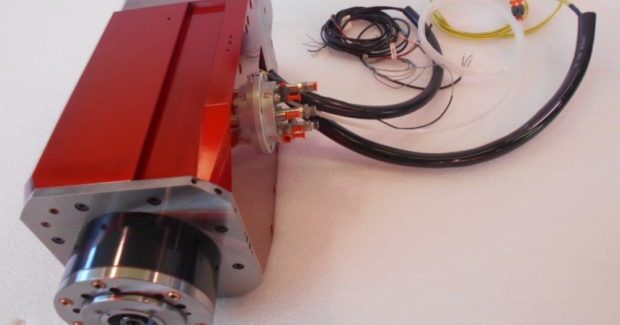

GTI Spindle Technology, Inc. (Manchester, NH) is the exclusive North American reseller for Peron Speed International Srl (Livorno Ferraris, Italy) and has worked together with them since 2013. GTI sought a relationship with Peron because of their diverse product line and complete spindle knowledge, as well as their high standard of quality craftsmanship. While machine tools are comprised of a whole host of pieces, the spindle is the most crucial component. Spindle repair and rebuild is the heart of what GTI does, and the company prides themselves on being able to handle any spindle that comes through their door. All spindles can be repaired, though the associated cost for some can eclipse that of a brand-new spindle. When this happens, they turn to Peron Spindle for a replacement.

Peron spindles are used heavily for critical production in high frequency ID grinding operations in the aerospace, automotive and OEM sectors where GTI specializes. By providing Peron replacement spindles, GTI can get shops back up and running with minimal downtime. Should users have an obsolete spindle and replacements are no longer manufactured, Peron can take the existing spindle and reverse engineer a completely new spindle, saving the user time and money from having to retrofit or replace machinery. Peron also does not require a set production run to manufacture spindles, enabling them to fabricate one-off spindles and saving GTI customers thousands of dollars in operating expenses.

With any spindle project, the specific situation must be fully understood: the shop’s needs versus their wants; their operating problems; and, most of all, their trust in addressing the operating issues. For example, GTI has a spindle design tech that has worked with one such company for over 30 years. This shop has 30+ machine tools with GTI-repaired spindles. Each machine tool has a grind spindle and a dresser spindle; Peron has built duplicate replacements for both types of spindles. In order to maintain production, the shop has always maintained a supply of spare spindles. Spindle life is far from a finite number, and it can vary from a few weeks to as much as two years.

A spindle can always be repaired, it is just a matter of making this process cost effective. Some companies will purchase new spindles when the repair cost is more than 50 percent of a new replacement, while other shops will allow repair spindles cost to go as high as 75 percent before replacing. Because repair cost for these particular spindles increased due to age and other factors, GTI took the initiative to discuss replacing some of the higher cost repairs with new spindles. Using their knowledge of the spindles and engineering expertise from the many repairs they had done, they approached Peron with spindle specifications for a design that would require no changes to the machines. Going to Peron with specifications that would make the new spindle a direct replacement and getting a quote for replacing those high cost repairs was a clearly cost-effective proposal.

In this case, GTI analyzed some of the high cost spindle repairs to determine which spindles should be replaced. Not only were the most recent costs reviewed, but several years of spindle repair history was also taken into consideration. Spindles that had a long history of expensive repairs were candidates for replacement, as opposed to a spindle that had only a recent one time high cost repair. Based on the cost of a new replacement spindle, a dollar figure was assigned that made a spindle repair questionable. GTI provided a list of spindles that fit this criterion and suggested a quantity of spindles to be replaced, as well as a cost justification for the replacement.

The three main factors to be considered for replacement were a direct replacement spindle, cost of repairs versus new spindles, and lost production. This meant the cost justification was based on new spindle cost, old spindle repair cost, and lost production due to spare spindles not being available. A total of four new spindles were purchased and are now being used to manufacture parts alongside the original spindles. Additional new spindles are also to be considered as the older spindles become too expensive to repair, since some of these spindles are over 25 years old. The relationship that GTI has with Peron allows them to provide outstanding field service and supply high quality spindles when repair is not an option.

GTI Spindle Technology, Inc., 33 Zachary Road, Manchester, NH 03109, 603-669-5993, info@gtispindle.com, gtispindle.com.