Current Trends & Challenges in Sawing Operations

Even a 50 percent reduction in actual cutting time only reduces the overall sawing efficiency by 20 percent at best, so efficiencies must be sought out in other areas of the operation. Here are some of the latest advances that are helping competitors in metal distribution and the metalworking industry find ways to cut their costs and increase their profitability.

Posted: October 16, 2017

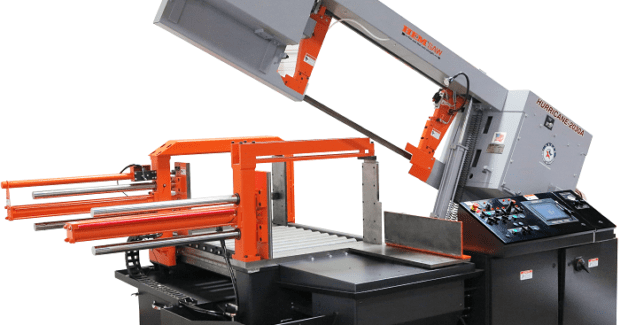

In today’s economy and facing stiff competition, companies in metal distribution and the metalworking industry are constantly asking for ways to cut costs and increase profitability. Most notably, their requests center on efficiency and reduction of process time: many shop owners and metal service center managers ask specifically how they can speed up their band sawing process to increase productivity and efficiency in their factories. In many cases, the issue they face is not only the saw choice or the sawing function, but a matter of wasted time in moving material into and out of the sawing operation.

MORE EFFICIENT MATERIAL FLOW

Careful time study assessments and analysis, conducted over years of studying and evaluating sawing operations in various types of facilities, has led to our realization that a more comprehensive approach to the sawing process – one that utilizes a “sawing system” design – is required. This concept, along with new and innovative control engineering, has improved the output of the sawing process exponentially. Even a 50 percent reduction in actual cutting time only reduces the overall sawing efficiency by 20 percent at best, so efficiencies must be sought out in other areas of the operation. One such study discovered that a customer had lost $3,132 during one ten-hour shift, and the majority of that loss was attributed to wasted time preparing for the next bundle cut, leaving the saw idle during the material handling process.

Material handling components have been created to improve efficiencies. The ability to move material through the primary sawing operation and, in many instances, into secondary and tertiary processes, is creating more efficiency and savings with increased material flow. As mechanical improvements to these material handling features advance, the focus has moved into design improvements in the control of the material handling components that combine with the saw in an “integrated” fashion. Not every business has the budget, or the need, for a fully automated material handling system. Components such as cross-transfers, powered roller tables, or side loaders might be overkill for a small operation, but there are still many budget-minded material handling features that can make a huge difference in the bottom line of any shop. When taking on any project, ROI must be taken into account that includes careful evaluation of the current process and cost-justification for any additional expense that is required.

MORE CONTROL OF THE SAWING PROCESS, LESS HUMAN INTERVENTION

Along with increases in productivity through more efficient material flow, fabricators are also demanding sawing systems that provide more internal management control of the sawing process. In response, there is now new PLC touch-screen technology with in-house programming to develop intuitive controls for both the saws and material handling systems. In addition, ‘non-contact’ material measuring devices utilize the latest sensor and motion control technology for accurate and time saving material measuring. Many automatic features are now integrated into the latest controls: functions and parameters that until just recently had to be known and entered by the operator are now programmed into the latest innovative touch-screen controls.

Many saw operators may not be completely familiar with the characteristics of the variety of materials they are expected to cut, the basic functions of band saw blades or how to select them, or even basic sawing concepts such as feed rates and cutting pressures. All of these are integral to efficient band-sawing and blade life, directly affecting operation costs and therefore profits. The operator has now been taken out of this equation with pre-programmed blade speeds, feed rates, and cutting pressures. Each of these parameters are programmed into the PLC touch-screen controls and stored in an interactive and modifiable material database “library” that is organized by both material type and size. This allows the shop to organize jobs with these cutting parameters already built in, saving time and money by preventing mistakes that could occur when an operator enters values that exceed the saw blade’s capabilities. It also provides parameters that produce efficient sawing along with maximizing blade life.

REAL-TIME MACHINE AND PROCESS MONITORING

Shop management is continually looking for ways to monitor their machinery and receive feedback in formats that are easy to evaluate and are actually useable for decision making. With upcoming control technology, equipment builders are developing controls that will use feedback devices to provide a wide range of machine and process monitoring, including predictive maintenance information. These sensors will allow efficiency monitoring and the controls will allow remote programming that can be set up to be accessed by the shop management and even by the builder if need be. The information gathered can also be tied into the shop’s ERP system for full integration of the data for management’s operational oversight. This automated monitoring will provide for longer machine life and less downtime. Functions such as the automated monitoring of fluid levels, as well as real-time cutting performance and output information, can equate to large savings for fabricators.

Another factor that is not possible with many manufacturers is the ability to make direct contact with engineers who are directly responsible for saw and control design. Because we do not outsource our design or manufacturing, our company provides this direct contact with our mechanical, electrical, hydraulic, and controls engineers for a more seamless resource in the selection and on-going operation of the sawing system. With this access, users of our equipment can have assurance that the appropriate component selection can be made, or a design can be custom-fit for their specific operation.