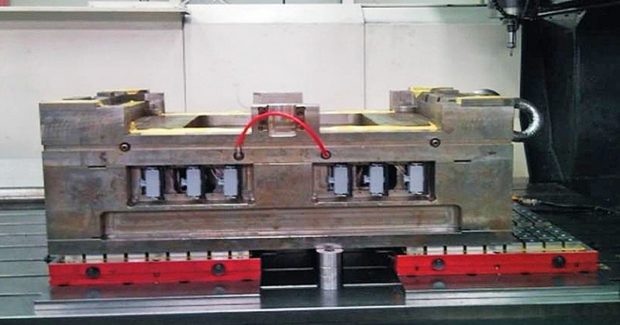

Injection Mold Clamping Magnets

Using proximity sensors for accurate positioning, injection mold clamping magnets from Techniks can be installed right over the existing platens to reduce set up time and take up less space, leaving room for fitting larger molds.

Posted: October 23, 2017

Techniks Inc. (Indianapolis, IN) offers mold clamping magnets for all sizes of injection mold machines. “Injection mold clamping magnets are a big improvement over traditional clamping methods because they reduce the time it takes to set up and change molds with features such as proximity sensors for accurate positioning,” states Michael Harris, the national sales manager at Techniks. “We’ve designed our magnet system with total adaptability in mind. The user’s mold setter can install it right over the existing platens.” Clamping magnets take up less space, leaving room for fitting larger molds. They eliminate mold deformation thanks to uniform clamping power and feature powerful rare earth magnets, ensuring that molds stay firmly clamped, even if a power outage occurs.

These magnetic chucks are a fast workholding system that reduces mold setup and/or change-over time by 50 percent and allows machining on five sides. Use magnetic workholding for all types of milling, drilling, thru-hole drilling and boring operations on all sizes of molds or other workpieces.

https://youtu.be/wVMzhlzAE5Y

Techniks Inc., 9930 East 56th Street, Indianapolis, IN 46236, 800-597-3921, Fax: 877-776-9994, info@techniksusa.com, www.techniksusa.com.