Precise and Versatile Large-Scale Gantry Multitasking

Ideal for the highly demanding requirements of parts used in the construction of machinery for the energy industry, the machining of marine and CHP motors, and the general machining of large parts, the PXG-W gantry-type multitasking milling machine from SORALUCE reduces the number of clamps required and reduces cycle times with less potential errors.

Posted: October 16, 2017

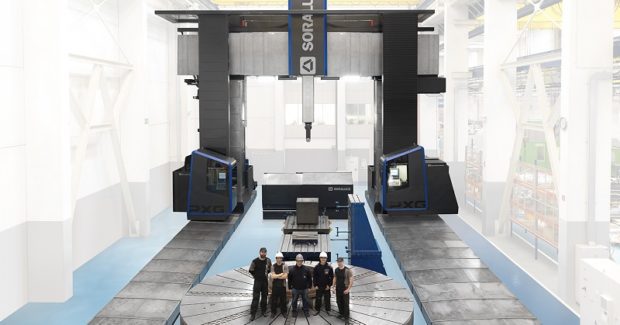

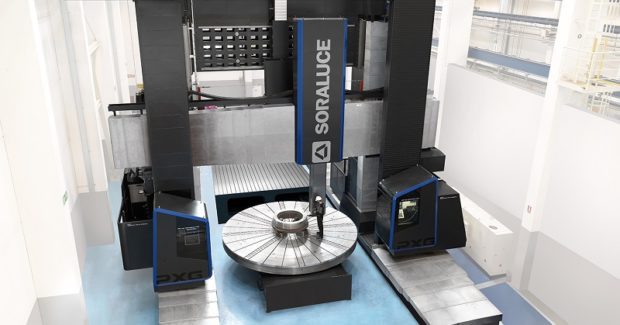

Machining large components calls for specific skills and machine tools that can handle extremely complex multitasking operations to maximize productive time and minimize set-ups. The PXG-W gantry-type multitasking milling machine from SORALUCE America, Inc. (Chicago, IL) reduces the number of clamps required and reduces cycle times and potential errors. It can work with centesimal tolerances on large parts that weigh hundreds of tons. The machine has a working volume of 1,000 cu m, weighs 500 tons, is 19 m long, has 7.25 m clearance between columns and is 7.3 m tall. Height is also configurable through the 5 m vertical travel of the crossbeam. This machine is designed to meet the highly demanding requirements of parts used in the construction of machinery for the energy industry, the machining of marine and CHP motors, and general machining of large workpieces.

The PXG-W performs different turning, milling, boring, drilling and threading processes with efficiency and precision by using several milling and turning heads with automatic tool changing. Its work area is split into two sub-areas: The surface of the main sub-area is for machining prismatic parts and is equipped with 12 m x 6 m floor plates with a load capacity of 25 t/m2. The second sub-area comprises a turning table with a hydrostatic mounting that features a 6 m diameter table with a load capacity of 150 tons. The turning head has a power rating of 200 kW with a maximum speed of 50 rpm that can handle large-scale roughing operations on large-sized parts from various sectors. The latest-generation Siemens 840D SL CNC enables both milling and turning operations on the same machine to reduce set-ups and avoiding difficult transportation and relocation operations when machining large components. It has two operator platforms, each with their own control panel so the operator can be in the best position for each operation.

Linear guides on the X, Y and Z axes avoid the thermal gradients caused by the flow of oil through the structure of the machine, ensuring better geometrical stability and substantially reducing the maintenance required. For a system of this scale, multiple simulations have been used to characterize the different deformations caused by displacement of the moving parts on the machine. To address deformations caused by the weight of those moving parts, an innovative patent-pending Vertical Ram Balance system (VRB) that consists of a CNC-controlled electromechanical system (also patent-pending) offsets the rolling caused by the torsion of the cross beam and the differential bending of the columns when the ram travels along the cross (Y) axis of the machine. This system ensures maximum precision in the perpendicularity of the X and Y axes, whatever the working position. A new thermal monitoring system checks for changes over time in all structural components via a function built into the CNC that has the latest thermal compensation algorithms. The turning table is fitted with sensors so that a function built into the CNC can be used to help the operator to re-balance the weight of parts with asymmetric geometries.

The machine structure is built entirely of cast iron for intrinsic stability and internal damping capability. The award-winning exclusive DAS (Dynamic Active Stabilizer) enables a damping effect to be actively incorporated into the structure to increase machine cutting capability up to 300 percent and reduce the risk of chatter or instability during machining. The Adaptive Control continuously adjusts the feed rate in line with power consumption to adapt it to tool capacity and process circumstances. The SSV system helps avoid the regenerative effect caused by certain chatter conditions during the process, and is particularly effective during large-scale boring and turning operations.

The PXG has seven milling heads for different geometries and power settings as high as 81 kW for machining a wide range of different parts, however difficult and inaccessible the areas to be machined may be. A magazine with three turning accessories can work with automatic or manual Capto C8 and prismatic tool clamping. Tool changes can be made automatically over the whole 5 m travel. The capacity of the on-board magazine is 180 tools. This complex machine is easy to operate due to the kinematics on the heads and accessories integrated into the CNC: the geometries of these elements can be compensated for and the working axes can be oriented automatically to facilitate and improve the operator handling experience.

The PXG-W machine competes within Industry 4.0 with a full monitoring package based on cloud computing. It incorporates real-time machine status, e-mail messaging in case of problems, reports on production and processes, energy consumption and performance during machining cycles, and diagnostics for key signals for the maintenance of the equipment. This is all done via secure connections routed through a PC or mobile device (smartphone or tablet) by accessing a single website online.

SORALUCE America, Inc., 875 N Michigan Avenue, Suite 3614, Chicago, IL 60611, 815-315-9261, Fax: 312-205-0358, www.soraluce-america.com.