The ‘Missing Link’ in Industry 4.0

The first open industrial network that offers gigabit Ethernet performance can now solve the first critical challenge facing the new generation of connected factories: bandwidth.

Posted: October 21, 2017

Much of the promise of Industry 4.0 is based upon seamless interconnectivity between production machines, enterprise systems and sources of data in the wider world. The Internet of Things (IoT) is a key foundation of that interconnectivity, providing low cost, easily integrated sensors, actuators and systems. Yet in most production environments today, true integration is rarely realized. Production networks need to communicate a wide variety of different data types, from critical real-time machine control signals to high volumes of recorded data from quality control systems and machine monitoring technologies. The differing technical requirements of these diverse data types can lead many organizations to implement multiple data networks. That adds complexity to system design, construction and maintenance. It makes data sharing across different types of equipment more challenging too.

To overcome these difficulties, manufacturers need a different kind of communication network. That network is now becoming a reality thanks to CC-Link IE, the first open industrial network offering gigabit Ethernet performance that solves the first critical challenge facing the new generation of connected factories: bandwidth. At 1 Gbps, it offers performance up to ten times that of similar protocols available today, enough to satisfy the most data-hungry modern manufacturing processes. The 1 Gbps network is not all about the speed – but the data capacity allowed by the increased bandwidth; this provides for true Industry 4.0 capability.

CC-Link IE is based on standard IEEE 802.3 Ethernet and offers great flexibility in network design, including ring, line and star topologies. The line and star topologies can be combined to provide systems that offer the maximum application flexibility. The ring and line connections are also attractive, as they permit simple “daisy chaining” of devices, meaning the added cost and complexity of network switches can be avoided. This industrial network also allows considerable application flexibility by supporting multiple protocol types on the same network to reduce costs and increase maintainability. In addition to the standard I/O control, it also offers safety (SIL3) and motion control on the same cable. This allows the CLPA to offer a cost-effective, simplified, flat network architecture that meets the needs of nearly all applications in the discrete sector.

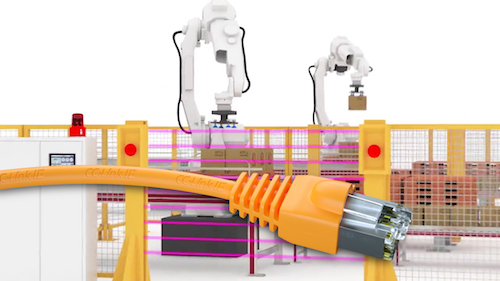

The network uses commercially available Ethernet infrastructure, such as standard gigabit switches, Cat5E cable and RJ45 connectors. A single network can incorporate a total of 120 stations with up to 100m of Cat5E cable between each station. In addition, as many as 239 networks can be interconnected. To further increase the network possibilities for end users and machine builders, the CC-Link Partner Association (CLPA; Vernon Hills, IL) has worked with PROFINET International (PI) to produce a specification for a “coupler” device that will allow these previously incompatible networks to be freely interoperable. Moreover, the CLPA is also working with the OPC Foundation to develop support for OPC-UA with CC-Link IE.

Unlike industrial protocols built on the standard TCP/IP (UDP/IP) stack, CC-Link IE combines the physical and data-link layers of the OSI hierarchy with an open protocol that extends from the network to application layers. The result is improved, inherent cybersecurity, thanks to an open, but controlled knowledge base that CLPA partners are free to implement, but reduces the exposure to unauthorized use. Critically for applications that combine industrial automation with enterprise systems and cloud or internet-based technologies, this industrial network can encapsulate TCP/IP (UDP/IP) packets for transmission across the network, allowing this traffic to “tunnel” through the CC-Link IE system.

CC-Link IE’s basic communication technique is based on a shared memory model. All the devices on the network occupy an area of the controller’s memory. To communicate with them, it’s only necessary to change the value of the data in the area corresponding to the relevant device. The network automatically handles the traffic via the standard “cyclic” (synchronous) communication. The same process happens in reverse for communication to the controller from devices. For high priority, unscheduled events such as alarms, or lower priority non-cyclic transmissions such as diagnostic information, an alternative “transient” (asynchronous) communication method is available. The gigabit bandwidth means that even high levels of transient traffic do not impact the deterministic regular cyclic communication, meaning normal system functions are not impaired and the scan cycle is completely deterministic.

Deterministic performance is achieved with a token passing method, allowing dependable system operation. In practice, this allows network update times to occur in a few tens of microseconds, depending on system size and configuration. CC-Link IE also offers the ability for redundant controllers, so even a controller failure will not necessarily result in lost production. In summary, this industrial network can help manufacturers reap the benefits of greater connectivity across their processes, with improved network performance delivering tighter control, greater data throughput at high speed, deterministic performance and inherent security. It is set to play a key role as manufacturers adopt Industry 4.0 models to address the production challenges of tomorrow.