Using Laser Trackers to Align a Particle Accelerator

Laser trackers are typically used to inspect parts and calibrate and align machine tools, but check out how this high energy particle physics laboratory uses them in the precision alignment of a particle accelerator that is more than ten miles long.

Posted: October 9, 2017

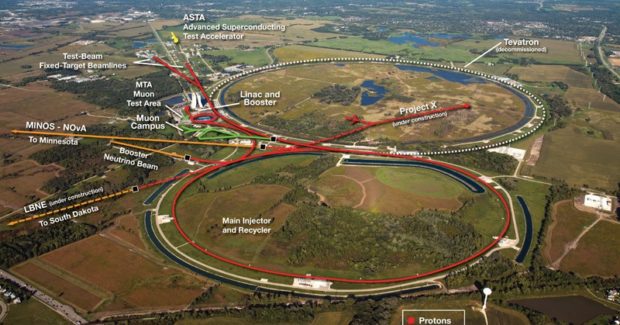

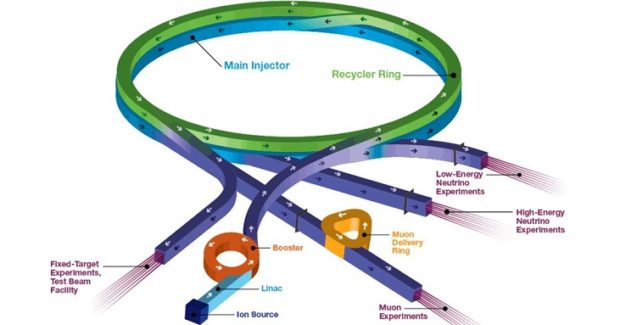

The research performed at the Fermi National Laboratory (Fermilab; Batavia, IL) tries to answer fundamental physics questions, such as how the universe began, what is dark matter and dark energy, what is the mass hierarchy of neutrinos, and are there other undiscovered particles beyond the currently known Standard Model? As a premier high energy particle physics laboratory, Fermilab operates some of the world’s most advanced particle accelerators on a 6,800 acre facility. These particle accelerators, with a total length of more than 10 miles, reside in tunnels 25 ft or more below ground. In previous years, the laboratory conducted colliding beam experiments. Now, in support of international neutrino research, they are transitioning into the world’s highest intensity neutrino facility, which requires a large amount of protons to be accelerated to very high energies before they strike a graphite target that generates secondary particles which, in turn, decay into neutrinos and other short lived by-products.

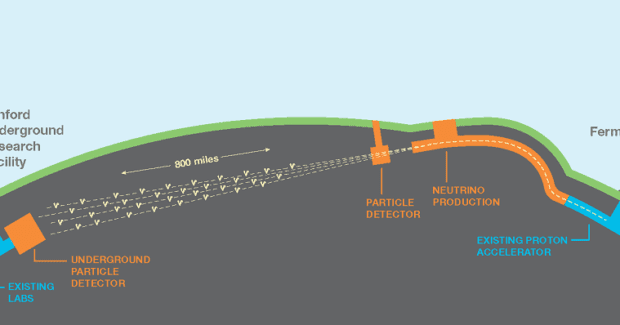

The charged protons reside in a vacuum tube and are guided by powerful magnets on a circular path while being accelerated to higher energies by radio frequency. In its final design, the accelerator will deliver 1.2 MW of proton beam power to a graphite target at an energy of 120 GeV, creating the highest intensity neutrino beam that travels through the earth to a liquid Argonne detector located at the Sanford Underground Research Facility (SURF; formerly the Home Stake Mine) in Lead, SD (see Figure 1). The alignment of the magnets is critical for an optimal operation of the facility. Fermilab utilizes Radian laser trackers from Automated Precision Inc. (API; Rockville, MD) during the installation and routine maintenance to position or inspect the dimensional integrity of the magnets in the Main Injector tunnel (see Figure 2). A maintenance period can last up to three months and requires utilizing laser trackers to facilitate a speedy alignment process.

Fermilab prefers to utilize the Radian laser tracker, which uses laser interferometer technology that is backed by the National Institutes of Technology Standard (NIST), a traceable standard that Fermilab requires in their quality inspections. The Radian is also used to lay the foundation for the alignment of the magnets in the form of a large-scale control network throughout the accelerator tunnel infrastructure. These reference points allow the end user to relocate the tracker anywhere within the tight tunnel enclosure while maintaining a connection to the global control network. As the Radian produces the best results in the range of 0 m to 30 m, corresponding to the visible line-of-sight in many of the accelerator enclosures, it became the natural instrument of choice for this task.

The Radian is also one of the most compact and least heavy instruments available. This is an important aspect for the alignment teams because, in many cases, the tunnel enclosure is only accessible through long and steep stairwells. The equipment must be hand-carried safely to the worksite. These days, laser trackers are utilized everywhere at all mayor accelerator facilities around the world.

LOCATING RADIATION HOT SPOTS IN THE VACUUM TUBE

In the transition of the laboratory into a neutrino factory, ever increasing beam power is required. This necessitates the upgrade of specific sections of the accelerator’s vacuum system. The existing vacuum infrastructure is not able to accommodate the increased beam size. This limits the machine operation and places a much higher demand on the alignment requirements for the vacuum pipes, which do not have reference markers but can only be determined by feature measurements.

In an effort to improve the measurement efficiency, Fermilab recently purchased an API wireless I-Probe and I-Scan II to support the feature measurement process of beam pipes. This I-Probe / I-Scan II combination allows the teams to quickly measure hidden points on the pipe and, in case of the I Scan II, acquire a pipe cross section with many data points in a very short time – thus reducing the time that the alignment crews may be exposed to higher radiation levels in these areas. These accessories allow the users to navigate in tight spaces within the tunnel that they couldn’t get to with just the API Radian and an SMR (a spherically mounted retroreflector used to target).

The backbone for most of the Fermilab alignment work is based on laser trackers in particular the API Radian. With the recent acquisition of the I-Probe / I Scan II, Fermilab enhanced their capabilities in the area of contactless measurements.

Automated Precision Inc., 15000 Johns Hopkins Drive, Rockville, MD 20850, 800-537-2720, Fax: 301-990-8648, info@apisensor.com, www.apisensor.com.