Done in One

Take a closer look at how some of the latest multitasking machining centers can increase your productivity and reduce your costs by machining complex parts complete with minimum set ups.

Posted: November 2, 2017

Complete Precision Machining of Large, Complex Parts

The Hyperturn 200 milling-turning center from EMCO handles large parts up to 1,000 mm diameter and 6,000 mm long, weighing up to 1,500 kg in the chuck and 6,000 kg between chuck and tailstock, and their Mecof Powermill traveling gantry 5-axis milling center permits the loading of huge parts of practically unlimited weight.

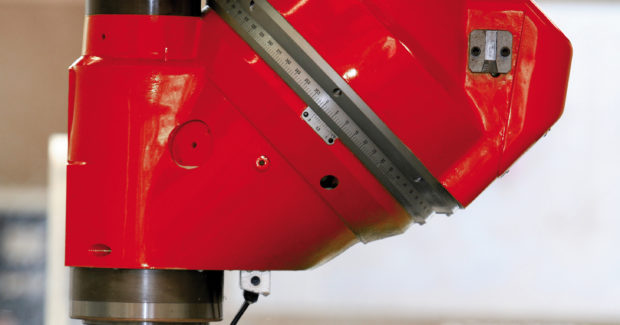

Precise and Versatile Large-Scale Gantry Multitasking

Ideal for the highly demanding requirements of parts used in the construction of machinery for the energy industry, the machining of marine and CHP motors, and the general machining of large parts, the PXG-W gantry-type multitasking milling machine from SORALUCE reduces the number of clamps required and reduces cycle times with less potential errors.

Multitasking Turning Center with Automated Load/Unload

The Nakamura-Tome NTRX-300 multitasking turning center from Methods Machine Tools has a built-in load/unload automation system and advanced operator recognition management software that completes parts in one operation using CAMplete TruePath Turn/Mill and NT Smart X Operation Software.

Complete, Complex Machining of Bar Stock

Quicktech i-42 Ultimate and i-60 Ultimate CNC turning centers from Absolute Machine Tools perform complete machining of medium diameter bar stock, including complex milling operations, using two turning spindles, two milling spindles and two B-axes for a total of ten axes and up to 49 tools.