The Power of Feedback

Take a closer look some of the latest technology used in machine condition monitoring and anti-restart protection for operator safety.

Posted: November 1, 2017

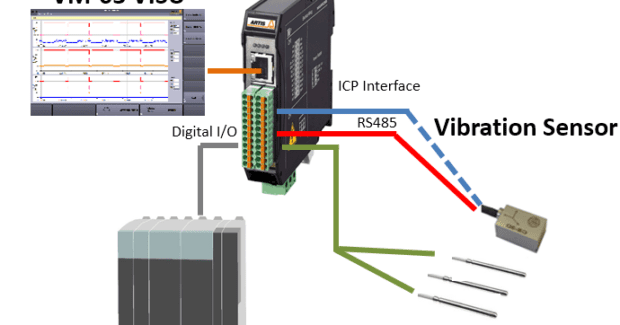

Spindle Vibration Monitoring, Temperature and Gravity Sensing

The Artis VM-03 vibration monitoring module from Marposs provides alarm output for acceleration in the form of warning, soft stop or hard stop, a temperature warning and a gravity value warning with registration of alarms occurring within +5 seconds of an event occurrence.

How to Protect Machine Operators from Accidental Re-Starts Following Power Interruptions

Sensing-Saf-Start motor controls from Rockford Systems prevent accidental machine start-ups after a voltage drop or power interruption by automatically disconnecting power to the machine so that when it is restored, the machine will not start up even if the power switch is in the “ON” position.

Gauge for In-Process Measurement Offers Time & Cost Savings

Ideal for measuring parts in harsh metal cutting environments, the Heidenhain-Specto ST 3087 RC length gauge from Heidenhain has an IP 67 level ingress protection to measure parts directly at the grinding, cutting, or forming location, instead of removing them to quality islands or laboratories.

In-Line Contour Measurement Systems

Alton Steel uses two CONTOUR CHECK EDGE 2-6 axes contour measuring systems from LAP Laser to measure their hot-rolled round and square profiles.