A New Approach to High Velocity Aluminum Destacking

Demand for stamped and formed aluminum components for vehicles has never been higher, but many shops face slower cycle times due to the difficulty of quickly destacking aluminum blanks. This new approach can significantly increase destacking speed up to 18 parts per minute with no multiple blanks – a significant productivity gain compared to the typical 12 parts per minute.

Posted: December 21, 2017

As truck manufacturers shift to more aluminum components for the performance and efficiency benefits of lighter-weight trucks, demand to accelerate the speed of aluminum forming operations has process engineers reviewing any and all constraints that limit gains in production speed. Some of these are hard limitations related to physics that simply can’t be overcome, but one of the constraints that can be reduced through process innovation is the speed of destacking blanks. New destacking technology is reducing speed barriers so that shops can increase their aluminum stamping throughput. One issue of lighter-weight blanks is recognized by anyone who has shuffled a deck of cards: they often fail to separate from one another. Stacked, flat objects have a tendency to stick together due to the suction created as they are pulled apart. This effect has long limited how fast aluminum sheets can be destacked.

This challenge is magnified by the oil or dry lube applied to the blanks to aid in the stamping process. As in many systems, what solves one problem often creates another problem. The fluids applied to the blanks create a light bond between stacked blanks, creating more difficulty in destacking them. Attempts to increase the destacking speed often results in picking up several blanks at once and risking disastrous consequences in the stamping or forming operation. This led to a trio of systems being designed for press rooms to speed destacking while ensuring consistent selection of a single blank. Two of these systems are widely used, while the third is a more customized design. By combining these technologies, a new approach can be created that significantly increases destacking speed up to 18 parts per minute with no multiple blanks – a significant productivity gain compared to the typical 12 parts per minute.

Traditional destacking systems rely on compressed air from the plant to separate the blanks. This new approach also utilizes compressed air, but instead uses a specialized nozzle to direct a high-pressure blast of air from a dedicated compressor. Plant air in traditional systems doesn’t typically provide sufficient pressure to consistently create the required separation, but this blast “flutters” the top blanks for initial separation. Next, a suction cup makes contact with the blank. Most conventional destackers lift the blanks symmetrically with suction cups, straight up from the stack, which maximizes the vacuum effect between blanks and increases the chances of picking up multiple blanks. This new approach, referred to as the pre-separator, positions the suction cups at the edge of the blank to lift from the end, then a fixture is quickly inserted under the top blank to keep the separation. This effect is similar to peeling a sticker off its backing paper, reducing the chance of lifting a second blank.

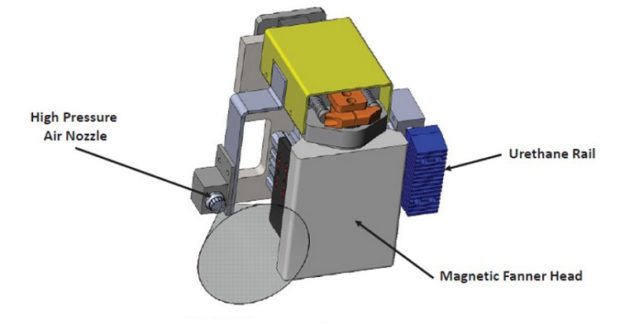

In traditional systems, the top blank and secondary blank can sometimes stick together with the high acceleration of the top blank as it is being lifted. The new approach addresses this by using a flexible urethane rail with wide bristles to knock down the second blank just below the blank being destacked (see Figure 1). These urethane rails retract to allow the second blank to settle back on top of the stack. A gantry robot removes the blank from the top of the stack and transports it to the conveyor, which represents another speed-improving innovation. Due to the light weight of the aluminum blanks, they often slip out of position on the belt if it accelerates too quickly. This automation system includes suction on the belt that holds the aluminum blank in the desired location as it quickly accelerates toward the stamping or forming operation.

When shifting from steel to aluminum blanks, press rooms often reduce stamping line cycle time for aluminum blanks compared to steel blanks because of the issues with destacking aluminum. Quick changeovers, from one part to another and from aluminum to steel, are critical to maximizing stamping productivity. This new system enables dramatically higher speeds, comparable to steel blanks, with increased productivity. It can be easily retrofitted on most existing steel destacking systems to minimize capital costs. Conversions have been completed in as little as four months. All of the other tooling and destacking devices work with both steel and aluminum, and are servo-controlled for fast, automated transitions between different metals or blank sizes. The changeover in this new destacking system is automatic and almost instantaneous from aluminum to steel sheets.

Güdel, Inc., 4881 Runway Boulevard, Ann Arbor, MI 48108, 734-214-0000, info@us.gudel.com, www.gudel.com

HOW TO IMPROVE GRIP PERFORMANCE ON HIGHLY CONTOURED OR OILY PANELS

Another innovation that can help accelerate the speed of aluminum stamping and forming operations are the new Deepdish Series Vacuum Cups from DESTACO (Auburn Hills, MI) that are designed to maximize grip performance on contoured and oily surfaces. They feature an all new bell-shaped body design, available in three sizes: 65 mm, 90 mm and 110 mm. Unique, molded-in gussets prevent the cup edges from rolling up on convex surfaces while the thin, pliable design and special inner tread pattern allow the cups to effectively adhere to flat, convex, concave, domed and oily surfaces for maximum grip performance. One key attribute that sets these Deepdish cups apart from others is their polyurethane materials-of-construction. Polyurethane provides superior wear resistance when compared to rubber to promote longer service life and reduced maintenance. Polyurethane also does not leave any marks on handled objects and has fantastic elastic memory, even after hundreds of thousands of cycles.

Deepdish cups have a durometer of 60 (PU60, translucent red in color) that makes it easier to pick up highly contoured panels while also being capable of withstanding the elevated shear forces that are created by increased acceleration and deceleration rates. Mounting options include traditional 3/8 in imperial NPT, 3/8 in Metric-G and 1.25 in square T-slot, along with a new lightweight plastic 3/8 in Metric-G model. All mounts are interchangeable with existing standard mounts. Installation involves unscrewing the old mount and replacing it with a new one, at most a 10 sec task.

DESTACO, 1025 Doris Road, Auburn Hills, MI 48326, 248-836-6700, Fax: 248-836-6740, www.destaco.com.