Easy and Flexible Automated Inspection of Large, Difficult Parts

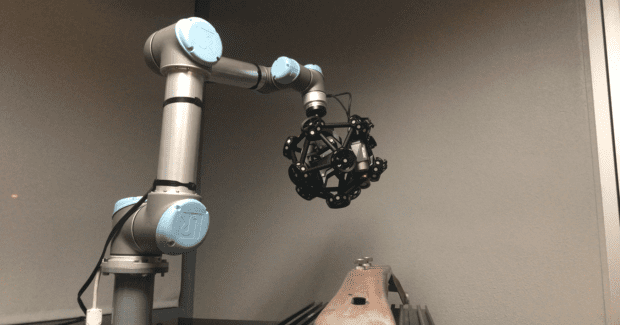

Universal Robots offers the Universal Metrology Automation system from 3D Infotech powered by Streamline on a UR5 cobot mated to a Creaform MetraSCAN-R laser scanner for flexible inspection of complex aerospace, automotive, consumer and medical device parts.

Posted: December 22, 2017

Universal Robots USA Inc. (UR; Ann Arbor, MI) offers 3D Infotech’s Universal Metrology Automation (UMA) system powered by Streamline, one of the most flexible automated quality control systems in the market, on a UR5 cobot (or any of their entire line of robot arms) mated to a Creaform MetraSCAN-R laser scanner for exceptional flexibility and ease of use that shops in aerospace, automotive, consumer products, and the medical device industries appreciate. The MetraSCAN-R scanner is very unique for its ability to rapidly scan and inspect large objects, even on difficult scanning surfaces, like chrome or black for example.

UMA captures a full 3D image of the physical part and compares this to CAD or manufacturing intent. UMA has demonstrated to be significantly faster, more repeatable, safer, and easier to use than manual gaging, CMM, or portable CMM. The entire line of Universal Robots works perfectly with UMA: it is inherently safe and simple to work with. Users implement in weeks, gaining a return on investment within months because they get a complete view of quality and how to address un-intended changes in the manufacturing process for any size of application.

UR also provides an E4H Tilt Cobot Series CoBase™ Table from LTW to maximize the cobot’s efficiency and ergonomics, changing its height and angle with the touch of a button. Why limit such a safe, intelligent, and helpful collaborative robot to a static position, height, and usability? With this table, workers of different heights can still use the same robot safely and ergonomically. Imagine how much more it can be used in the shop if it can be raised, lowered, and tilted. These E4H Tilt Cobot Series CoBase Tables come standard with the following features:

- Soft Touch Button with Presets for Lift and Tilt.

- Heavy duty 3 in x 7 Ga Welded Square Tube Steel

- 12 in Stroke Lift Height

- 2,200 lb Lift Capacity Standard

- Powder Coat Wheel Grey Standard (Optional custom colors)

- Heavy Duty Casters

- Fork Lift Tubes

- Dual 120 VAC Outlet

- Power Cord Wrap

- Soft Touch Button with Presets for Lift and Tilt

- Shipped Assembled and Ready to Use

Options include, but are not limited to:

- Extra Heavy Duty Linear Actuators

- Electrical Box Mounts

- Fork Lift Tubes

- Specific tabletop bolt hole patterns for any cobot

- Aluminum

- Steel

- Blanchard Ground Steel

- Maple Block

- Laminated

- ESD Laminated for Anti Static Applications Table Tops

Universal Robots USA Inc., 5430 Data Court, Suite 300, Ann Arbor, MI 48108-8944, 844-462-6268, www.universal-robots.com.