Fast, Reliable Production of Automotive Die Cast Parts

The a40 horizontal machining center from Makino not only reduces per-piece cost, it also achieves savings that affect capital investment, labor, floor space, utility consumption and durable tooling.

Posted: December 13, 2017

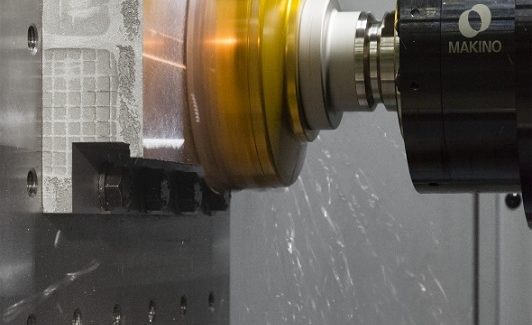

Machine tool selection for the die cast market has typically been limited to general-purpose horizontals that possess unnecessary capabilities and result in extended cycle times in the machining of near net shape die cast parts. But the a40 horizontal machining center from Makino, Inc. (Mason, OH) is built for non-ferrous die-cast parts machining. “Die cast manufacturers are under intense pricing pressure with mandatory cost reductions from OEMs and increasing global competition. The keys to overcoming these challenges lie in the reduction of machining cycle time and elimination of unplanned down time,” explained David Ward, the horizontal product line manager for Makino. “To address the cycle time issue, we re-evaluated each of the major castings using an Intelligent R.O.I [Reduction of Inertia] design philosophy and created a design with superior linear and radial agility and acceleration.”

The Intelligent R.O.I. design of the a40 is a collection of innovative technologies designed to slash un-productive non-cut times from part processes, including:

- Responsive CAT40 spindle acceleration to 12,000 rpm in 0.5 seconds.

- Quick completion of common tapping operations with 6,000 rpm rigid tapping synchronization speed.

- An average of 29 percent faster time to full rapid traverse rate, minimizing common feature to feature positioning time.

- Optimal acceleration performance of multiple machine systems with evaluation of fixture and tool weights through Inertia Active Control (IAC) technology.

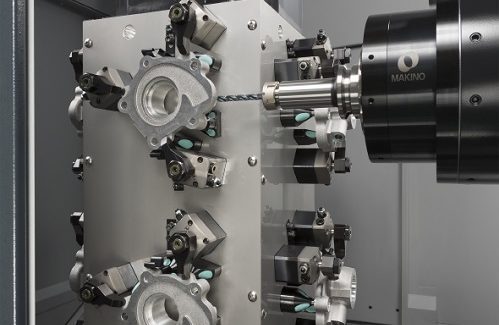

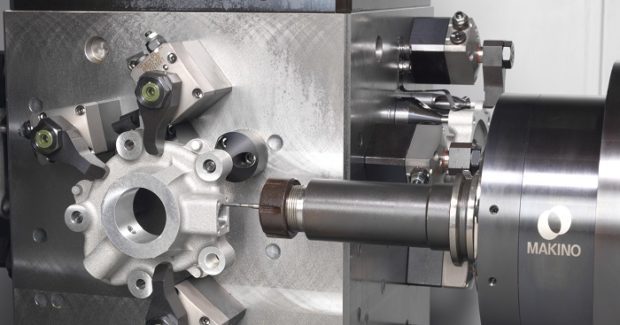

The ability of the a40 to reduce part machining cycle time not only cuts down on per-piece cost, but also has far-reaching savings that affect capital investment, labor, floor space, utility consumption and durable tooling. It offers a 400 mm pallet with a workpiece capacity of 630 mm (24.8 in) diameter by 900 mm (35.4 in) tall, making it an ideal platform for die cast parts commonly machined in the automotive industry. Axis travels of the machine are 560 mm (22.0 in), 640 mm (25.2 in) and 640 mm (25.2 in) in the X, Y and Z planes, respectively. Maximum payload is 400 kg (880 lb). This machine also offers numerous features and capabilities for improved utilization and reductions in non-cut time, including a 40-position automatic tool changer and an automatic pallet change system to ensure uninterrupted operation.

Unplanned down time is devastating to high volume die cast production machining, making the reliability of the machining system paramount. The a40 utilizes single-piece X- and Z-axis covers, center trough chip and coolant management, and dual-supported ATC mechanisms for exceptional reliability throughout the life of the machine. It also has:

- Standard Vision type broken tool detection that supports unattended operation by quickly validating the condition of the cutting tools after each tool change.

- Dedicated tool taper cleaning nozzles wash the tool taper with 20μ filtered coolant with each tool change, ensuring contamination free tool clamping.

- Three stage coolant filtration with 20μ hydro-cyclone eliminates coolant tank sludge common with aluminum machining, extending time between coolant system PM or cleaning.

Makino, Inc., 7680 Innovation Way, Mason, OH 45040-8003, 513-573-7200, Fax: 513-573-7360, www.makino.com.