Fewer Pieces, More Business, All Fast

The flexibility, accuracy and speed of universal cylindrical grinding built this job shop a reputation for fast deliveries, superior part finishes and versatile machining of high quality prototypes and critical automotive and trucking parts, and quick turnarounds of fixtures to reverse engineer worn/broken parts.

Posted: December 12, 2017

To remain a successful job shop, J.H. Benedict Company, Inc. (East Peoria, IL) relies on their ability to perfectly execute any and all jobs proposed by customers. This requires a versatile skill set with flexible functionality in their machines and employees. Their work comes from a variety of customers in the automotive, trucking and other industries that need high quality prototypes and fixtures to reverse engineer worn/broken parts. They approach J.H. Benedict to either quote an original design or develop and refine a final design from their own concept. After proof of the concept, the shop works with production supplier engineers to further improve the product and its tolerances. Because J.H. Benedict relies on these short run jobs, as opposed to a few large run batches, each piece of equipment on the shop’s floor must be as flexible as possible, including its grinding operations. “Versatile machines are the key to our business model,” noted plant manager Austin Jones. “We need equipment that can do everything.”

Established in 1945 as a tool and die shop, the company acquired their first CNC equipment in the 1980s to begin producing molds. They eventually shifted into mainly machining prototype parts. Today, the shop listens to engineers to learn how pieces must fit together so they can design parts to meet specifications. As the shop transitioned to prototypes, their old grinding equipment was no longer meeting their needs. The company researched new CNC grinding technologies that provided the performance they required: they had to increase speed to shorten lead times for delivery, and parts needed to be more accurate. With fewer pieces in a run, the demand for production efficiency was higher than ever before, meaning any new machine had to be versatile.

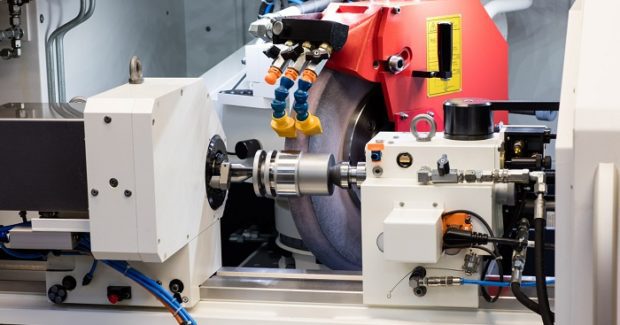

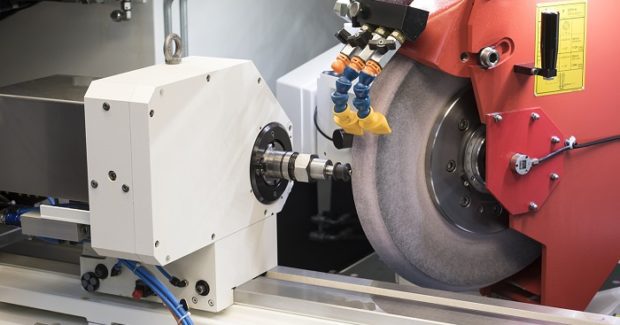

The shop chose a Studer favoritCNC universal cylindrical grinding machine from United Grinding North America, Inc. (Miamisburg, OH) because its multiple axes offered adaptability, accuracy and speed. “We wanted to do grinding with CNC axes that hold tighter tolerances,” recalled Austin. “This machine has the necessary repeatability for our requirements. Its thermostability ensures that we don’t have to scrap parts, which is especially important to our small runs.” The favoritCNC is designed for producing individual or small-run medium-sized parts, which is important for grinding orders that may only consist of a couple pieces. The favoritCNC is also easily retrofitted to perform other grinding tasks.

As a job shop, J.H. Benedict grinds a broad range of part sizes and materials. The smallest parts measure under .125 in diameter, while the largest parts are up to 13.5 in diameter. Materials include aluminum, stainless steel and 86-20 steel that are ground with ceramic wheels, and rubber that is ground with an aggressive aluminum oxide wheel. Equipped with an auto-balancer that makes wheel changes fast and easy, the favoritCNC has dramatically reduced shop setup times. An additional boost to setup speeds comes from the shop’s stock of several different versatile wheels that perform well in multiple applications. An additional time saver is the StuderGRIND software, which is equipped with pre-set, standard grinding programs that can be tailored to an application. The time necessary to setup a part is reduced by the operator editing a pre-set program, instead of creating one entirely from scratch. These programs can be saved and reused over time as multiple jobs are run in small batches.

The reliability and consistency of this universal cylindrical grinding machine guarantees that exactly the right amount of material is ground away every time. It reduces waste by significantly reducing error over what an operator could accomplish with manual grinding. Typical turnaround time is two to four weeks depending on the complexity of the job, but the shop will go above and beyond when the situation calls for it. Customers are so reliant on quick responses that some have sent a driver with a critical part on an eight-hour drive to the shop. After arrival, the shop works overnight to get the part done while the driver stays and watches over its completion. Once finished, the part and the driver return to get the customer back up and running.

This grinding equipment has aided the company’s growth and the shop’s reputation for fast turnarounds, superior part finishes and versatile machining capabilities that consistently bring them new customers.

United Grinding North America, Inc., 510 Earl Boulevard, Miamisburg, OH 45342, 937-859-1975, Fax: 937-859-1115, info@grinding.com, www.grinding.com.