High Precision Coil Processing Lines for Fineblanking Brake System Components and More

The Fineblanking Edition HD straightener in high precision coil processing lines from COE Press Equipment addresses coil set and crossbow issues necessary to achieve the flatness required for producing near net shape blanked parts.

Posted: December 7, 2017

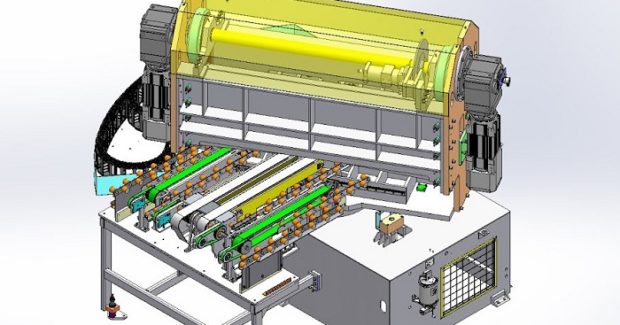

High precision coil processing lines from COE Press Equipment (Sterling Heights, MI) are well suited to fineblanking applications. They rely upon a Fineblanking Edition HD straightener that can address both the coil set and crossbow issues necessary to achieve the flatness required for producing near net shape blanked parts. Compared to other straighteners, the Fineblanking Edition provides increased roll force delivery, stronger gears and bearings, and an improved straightener roller backup mechanism for increased rigidity. “The precision built into our straightening heads enables us to offer feed lines capable of achieving the flatness and tight tolerances required for fineblanking that help efficiently deliver specialized stampings with high dimensional accuracy,” says Steve Donnay, the director of sales and marketing for COE.

Fineblanked parts are often produced from thick and high-strength material that can be dangerous to handle manually. To address this issue, these fineblanking lines feature coil reels with multiple hydraulic hold downs with motorized endwheels for effective coil containment. The mandrel and motorized endwheels rotate in unison for effective threading and rewinding. Additionally, a pivoting “alligator” style peeler-debender offers a hands-free, modular approach to threading. These fineblanking lines can process materials at widths from 1.0 in to 36.0 in, thickness up to .500 in, and coil weights up to 40,000 lb. They can process materials with yield strengths up to 1,000 Mpa while holding flatness tolerances of .003 in TIR per square foot. COE recently installed a 5 in x 24 in Fineblanking Edition HD straightener, coil reel with HD hold-down arm and “alligator” style peeler threader at Util Canada Ltd (Concord, ON), a leading backing plate manufacturer in North America. The equipment includes a 24 in x 18 in threading table with hands-free threading capability and a 15,000 lb x 24 in coil reel with multiple hydraulic hold downs with motorized endwheels for effective coil containment. This equipment is capable of processing high strength steels up to 90,000 psi yield at thicknesses from 0.118 in to .475 in, depending upon the width of the material. It can achieve a payoff rate up to 80 fpm. COE also provided the shop with startup and training assistance.

COE also offers their new Oscillating Servo Shear that significantly reduces maintenance time and costs, and provides energy savings and noise reduction over conventional hydraulic shears. The smooth operation of this servo shear can cut both rectangular and trapezoidal blanks with reliable, repeatable precision. “By eliminating the hoses, the fluids, the air, the clutch and all the energy associated with hydraulic systems, this product offers shops many advantages,” notes Donnay. Totally self-contained, this new servo shear relies upon a slew ring to support the weight of the shear. This design allows the shear to swivel in back and forth with the help of a second servo axis, attaining different angles for the cut. The Servo Shear can handle coil materials from 24 in to 78 in wide and up to 0.25 in thick. When run in continuous mode, the system is capable of reaching speeds of up to 240 spm, depending upon the width of the material being run.

With hydraulic systems that are constantly under high pressure and high flow rates, components tend to deteriorate: hoses chafe, fittings come, fluids and filters have to be changed regularly. A servo system eliminates all the piping, hoses, filters and much of the lubricant for ease of maintenance. Gravity has little effect on a servo motor in a resting state, requiring very little energy to hold it in a balanced position between cycles. Compare that with hydraulic systems, where the power unit runs at the same rate all the time, regardless of whether the shear is cycling or not, and energy is constantly dissipated through heat loss. Additionally, the clutch and brake also require energy and compressed air, where large amounts can be expended into the atmosphere. This Servo Shear moves in a very smooth, controlled sinusoidal motion that is very quiet in contrast to the top and bottom slamming of a conventional shear.

COE Press Equipment, 40549 Brentwood Drive, Sterling Heights, MI 48310, 586-979-4400, www.coepress.com.