Laying Groundwork for Great Laser Cutting: Start with the Slats

Though it is often overlooked by equipment users, one of the most critical factors to consistent laser cutting quality is the proper maintenance of the worktable where the cutting process takes place.

Posted: December 11, 2017

One challenge that fabricators working with laser cutting systems must address is the fact that quality cut parts depend on a well-tuned machine. While advances in technology over several decades have resulted in laser machine tools that are productive, capable and reliable, all of these machines still depend on good maintenance and accurate operating parameters to remain efficient through many years of production. In the daily quest for perfect laser cut parts, it is natural to focus on the obvious factors: Are my cutting parameters, such as gas pressure and feed rate, set correctly for the material? Are my consumable parts, such as cutting head optics and nozzles, in proper working condition? However, one of the most critical factors – often overlooked by equipment users when it comes to consistent cutting quality – is the worktable where the cutting process takes place.

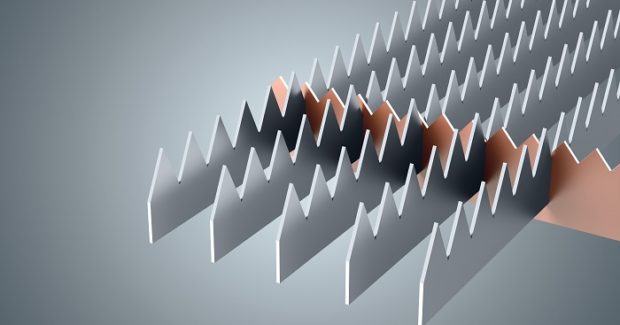

The majority of laser cutting machines that have been designed and sold over the last 40 years operate under the same configuration: the cutting head traverses over the sheet being cut, which in turn is supported by a metal grid (the worktable or pallet). During the laser cutting process, gas is blown onto the sheet metal while the heat of the laser works to melt it. Gas and molten metal must be expelled from the bottom of the cut in order to create a clean kerf and separate good quality parts from the sheet. However, this ejection does not occur cleanly when the bottom of the sheet is blocked, thereby making a solid worktable out of the question. Laser slats are designed to present the minimum possible surface area to the bottom of the sheet, limiting blockage of the molten ejecta while still providing the necessary support to the raw sheet and finished parts. Striking a balance between proper support and minimal interference with the cut parts has led to a lot of different design ideas for laser worktables, but at the end of the day they are always some sort of metal grid.

Since cleanly removing the molten material equates directly to a high quality cut edge, maintaining the laser slats is critical for reliable production. Over time, the excess molten metal derived from the cutting process will tend to cool and solidify on the slats. This will cause slag to build up and reduce the amount of effective surface area on the worktable and ultimately create more dross to cling to the bottom of the cut parts. This also contributes to blocking the laser cut, which can cause the cutting quality to deteriorate to the point where the laser begins to weld rather than cut. In the very worst cases of slag buildup on the worktable, parts and even entire sheets may become welded to the slats, resulting in significant waste and downtime. Cutting out new slats and replacing the worn out ones comes at a cost, but the cost is much lower than that of operating on poor slats.

Some users will chisel slag off the slats to keep them in good working order without replacing them. This can save material, but it is still labor intensive. Other shops use power tools that are specifically designed for removing slag from laser slats, which can be an extremely cost effective way to maintain the worktable.

Another consideration with laser worktables is the design of the grid. Many lasers intended to work with material handling automation require a specific arrangement of slats, so changing the layout of the support grid is impossible. However, when lasers are not automated the user has the option to modify the grid configuration. Spacing slats closer together can provide better support for cutting smaller parts, reducing the chances of a piece tipping and colliding with the cutting head. While many lasers are delivered from the manufacturer with slats arranged in parallel rows, some users have found that replacing these with a crisscross grid of slats similar to an egg crate pattern improved cutting reliability and reduced tipping issues. Since the crisscross design is also stronger than parallel rows of slats, the thickness of the slats could be reduced (for example, from 0.125 in to 0.040 in) to further reduce the cost of maintaining the worktable.

Lastly, depending on the area of application that the laser machine will be used for, changing the type of material used for the slats might be worthwhile. Some industries exchange the standard mild steel slats for different materials due to product concerns. Sometimes, stringent welding requirements may also necessitate the laser support grid to be made of the same material as the product to be fabricated. For example, shops that laser cut stainless steel for food service or medical applications may require the use of stainless steel worktable slats in order to prevent contaminating the finished product with steel dust or slag. In some applications, particularly the cutting of very thin sheet thicknesses, slats made of copper have been found to resist slag accumulation better than steel slats. In these instances, slats made from a more expensive material may be a more cost effective option.

Testing different slat solutions in a small area of the laser worktable is often the best option and way to verify if the results are worthwhile before reworking the entire pallet. The diversity of products now being fabricated with laser cutting systems means that there isn’t a single solution that will work ideally in every business and for every situation. The important thing to keep in mind is that neglecting the machine’s laser slats will ultimately increase the cost of the laser cutting operations. For shops that strive to achieve the highest degree of value with the lowest possible waste, proper maintenance of the laser worktable is absolutely critical and will lay the foundation for a profitable laser cutting operation.