Powerful, Flexible Fiber Laser Cutting for Trailer Body Manufacturers

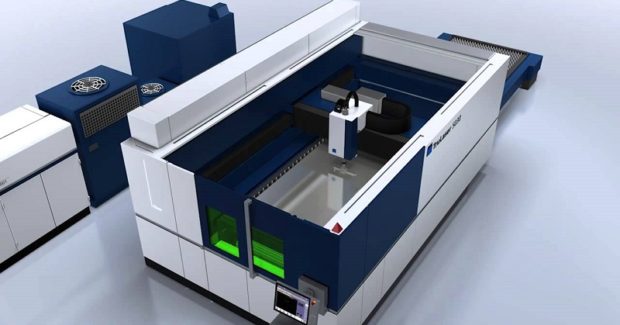

Using HighSpeed Eco cutting technology with a newly designed bi-flow nozzle that minimizes nitrogen consumption while maximizing productivity, the TruLaser 5030 fiber laser from TRUMPF can process complex contours and power through mild steel up to 1 in, stainless steel up to 1.5 in and aluminum up to 1 in.

Posted: December 7, 2017

The TruLaser 5030 fiber equipped with a 10 kW TruDisk laser from TRUMPF Inc. (Farmington, CT) powers through mild steel up to 1 in, stainless steel up to 1.5 in and aluminum up to 1 in. The machine’s patented HighSpeed Eco cutting technology minimizes nitrogen consumption while maximizing productivity using the newly designed bi-flow nozzle. As a highly productive universal machine, the TruLaser 5030 fiber is able to process complex contours and thin to thick sheets while keeping the cost per part to a minimum. The BrightLine fiber, CoolLine, and PierceLine functions guarantee high quality laser processing in thicker materials as well. CoolLine stabilizes the cutting process in steel by use of targeted cooling that results in greater material tolerance while enabling more intricate material contours and a tighter layout of parts. PierceLine improves piercing capabilities so the laser can process smaller contours while significantly boosting speed.

To take full advantage of the TruDisk 10001 laser, the machine is designed to achieve high acceleration and axis speeds for significant productivity gains in medium thickness materials. Its new Smart Nozzle Automation with the integrated nozzle inspection feature includes the option to load and unload nozzles while the machine continues cutting. This minimizes setup time and operator intervention to maximize productivity. The TruLaser 5030 fiber also rapidly marks durable Dot Matrix Codes on processed parts so that the parts are easily identified and tracked in subsequent operations, making this machine a key component in any Industry 4.0 application. A new multi-touch display simplifies the user interface to make the TruLaser 5030 fiber easy to learn and operate.

The Drop&Cut feature aids in cost effective production and enables operators to easily use part skeletons for additional production. They are provided with a live image of the machine’s interior on the control unit’s user interface. From the control unit, the operator simply clicks or taps the screen to drag the programmed contour to the desired location on the projected sheet and initiates the cut. With the new TruLaser 5030 fiber, the process is conveniently managed from a new and ergonomic 19 in control panel that can be adjusted to an ergonomic height.

TRUMPF also offers the TruMark 5050 fiber marking laser with an adjustable pulse length that is flexible and able to process a diverse range of materials with impressive results using VisionLine Mark image processing software. High beam quality and high average power make the TruMark 5050 the ideal laser for engraving. Short pulses enable very precise energy input for highly accurate marking, while longer pulse durations increase the productivity of the system. It is also possible to increase productivity with an optional dual head system. Using two scanners, two parts can be processed simultaneously. Operating in the infrared range (1,062 nm) and with an adjustable pulse duration from 7 ns to 500 ns, the TruMark 5050 is able to cover a broad spectrum of diverse applications for automotive parts.

TRUMPF Inc., Farmington Industrial Park, 111 Hyde Road, Farmington, CT 06032, 860-255-6104, www.us.trumpf.com.