Systems for Medium- and Heavy-Duty Industrial Welding

Aristo industrial welding systems from ESAB combine new and improved components in 21 ready-to-weld packages that increase quality and lower the cost of operation in welding aluminum, stainless and carbon steel.

Posted: December 15, 2017

By combining new and enhanced components, ESAB Welding & Cutting Products (Florence, SC) has launched an expanded series of Aristo® industrial welding systems that provides greater productivity, better quality and lower cost of operation for welding aluminum, stainless and carbon steel. New equipment includes the Aristo Feed 4004 HD heavy-duty feeder with U82 Plus or U6 panel and the highly intuitive MA25 Pulse Panel for advanced and conventional welding processes. Enhanced systems include the Aristo MIG 4004i Pulse power source, a 400-amp CC/CV power source that now features quicker responding hardware for better arc performance, a new start parameter for more positive arc starts, Short Circuit Termination (SCT) for better weld termination/arc starts and more rugged components for longer life. The Aristo Feed 3004 wire feeder has also been enhanced with a more robust wire feed motor, new drive roll stand with excellent feed roll alignment and polished U-groove feed rolls for aluminum wire.

“In conjunction with the existing 500 amp CC/CV Aristo MIG 5000i power source and these new and enhanced Aristo systems, we now offer 21 ready-to-weld packages to meet the needs of medium- and heavy-duty industrial welding operations,” says Doug Smith, the product business manager of light/industrial arc equipment for ESAB. “From simple to highly advanced pulsed, we offer systems that best fit user technology needs and budget parameters.” He notes that, with the need for continuous cost reduction and quality improvements, more fabricators can benefit from wire feeders, control panels and power sources that offer advanced functions.

The Aristo 4004 HD can feed .030 in to 3/32 in wire at speeds of 50 ipm to 800 ipm in the heavy fabrication of trailers and transportation equipment. It is available with a U6 control panel that offers 60 pre-programmed synergic lines or a highly advanced U82 Plus control panel that offers 250 pre-programmed synergic lines and patented SuperPulse™ processes. The Aristo Feed 4004 HD can reduce cost of operation by up to 50 percent or more through its drive roll, which combines two lower gear-driven rollers with two upper idler/smooth pressure rollers. This design produces considerably less scrubbing of the wire, reducing debris generation by 8 times to 12 times that typically created from a 4-roll drive system. Reduced debris extends liner life by 30 percent to 60 percent, and an upper idler system doesn’t mar the wire like a 4-roll drive system, resulting in 4X to 6X longer contact tip life with cored wires.

Users only need to buy two drive rolls instead of four, an instant 50 percent reduction in drive roll cost (average feed roll life is four to eight weeks, depending on the application, and drive rolls cost range from $41.20 to $46.35 for a set of two). Standard features include gas purge, inch wire, trigger lock (2T/4T control), burnback, slow run-in, the ability to preset wire feed speed and voltage and a digital display that shows volt, amps and wire feed speed. Standard processes are synergic GMAW, synergic GMAW-Pulse, Stick, DC lift TIG and air carbon-arc gouging (limited by the size of the power supply). The feeder also incorporates Short Circuit Termination (SCT) technology that sharpens the end of the solid MIG wire at the termination of a weld. By eliminating the ball that typically forms on the end of the wire, the feeder optimizes the wire condition to promote a positive arc start. SCT technology also eliminates the need for the operator to clip the wire: in an operation with numerous weld stops and starts, time savings add up quickly. To improve arc starts when using Flux-Cored or Metal-Cored wires, use the burnback setting.

Fabricators want the traditional benefits of pulsed MIG welding in a more operator-friendly package, and the new MA25 Pulse panel is the heart of the system, using icons, push buttons and digital displays to simplify use and eliminate language barriers. Different welding programs are easy to find, set and fine-tune for improved productivity. To begin pulsed welding, operators select the synergic line for the type of filler wire and gas being used. The system then provides optimum dynamic arc control; no additional process knowledge is required. The system can automatically adjust for variations in arc length (voltage) and wire feed speed, helping to maintain consistent penetration and weld bead appearance. The MA25 Panel provides the next level of quality improvements or helps less experienced welders produce better results. The MA25 Aluminum Panel features 30 synergic lines for aluminum, and the MA25 Steel/Stainless Panel provides 54 synergic lines for solid and cored wires. The MA25 Pulse panel connects directly to the Aristo Feed 3004 wire feeder.

Depending on the application, pulsed GMAW welding provides numerous benefits, including:

- Standardize on a single, larger diameter aluminum wire for welding a broad range of metal thicknesses.

- Greatly reduce or eliminate weld spatter and associated post-weld clean-up.

- Control bead appearance, an important factor when customers value good-looking weld beads.

- Weld thinner materials without burn-through or warping, increasing first-pass yield and reducing scrap rates.

- Better manage heat input to preserve mechanical properties while also increasing travel speed, especially on stainless steel.

- Enable all-position welding while maintaining reasonably high deposition rates and travel speeds.

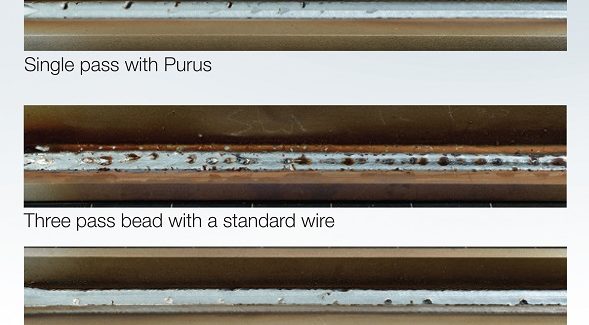

In addition to pulsed MIG, all of these advanced panels feature QSet™ that automatically optimizes the short circuit MIG arc for the gas/wire combination installed, then adapts welding parameters to match an operator’s individual welding style. ESAB has also introduced PURUS™ 42, a next-generation solid wire formulated to reduce post-weld cleaning of spatter and silica islands. It is classified as an AWS ER70S-6 EN/ISO G3Si1 wire and available in diameters from .030 in to .062 in. “We enhanced the metallurgy of PURUS wire to reduce formation of silica islands so that slag self-releases or easily brushes off,” explains Mikael Mimer, the global product line manager solid wires for ESAB. “This wire can reduce post-weld cleaning time and unplanned downtime associated with spatter, reduce or eliminate downtime for removing silica islands in multi-pass welding, and reduce or eliminate paint-related quality issues.”

PURUS is available in two wire types: as a bare wire with the same superior advanced surface characteristics used on OK AristoRod™ wires, or with a state-of-the-art copper coating. Both versions deliver a stable process with superior arc stability and minimal spatter. In either formulation, PURUS delivers results users can monetize, especially in high volume semi-automatic and robotic applications. At one manufacturer of construction equipment, PURUS reduced arc ignition errors by 66 percent in multi-pass applications. “Previously, excess silica islands prevented positive arc ignition,” notes Mimer. “When this occurred, the shop needed to shut down their robotic welding station, spending an average of three minutes to clean the silica islands. With an hourly rate of $280/hr in the station, each stop cost $14.”

PURUS meets all the technical requirements for an S-6 wire, enabling users to change wires without requalification. To provide batch-to-batch consistency, PURUS wire uses the most tightly controlled range for the three primary alloying elements of a mild steel wire: carbon, manganese and silicon. In addition, ESAB tightly controls a total of 17 raw elements. This wire provides good wetting so that the weld puddle flows nicely, with a smooth transition at the weld toe. It creates a better bead profile and better surface appearance so it can reduce or eliminate the need for TIG dressing or grinding to remove stress concentrations.

ESAB Welding & Cutting Products, PO Box 100545, 411 South Ebenezer Road, Florence, SC 29501-0545, 843-669-4411, Fax: 843-664-4258, www.esab.com.