Where Carbide Matters in Modular Drilling

The KenTIP FS modular drill from Kennametal uses a full solid carbide front to withstand more heat and abuse, and smooth, highly polished flutes that greatly improve chip evacuation and reduce wash out near the tip.

Posted: December 19, 2017

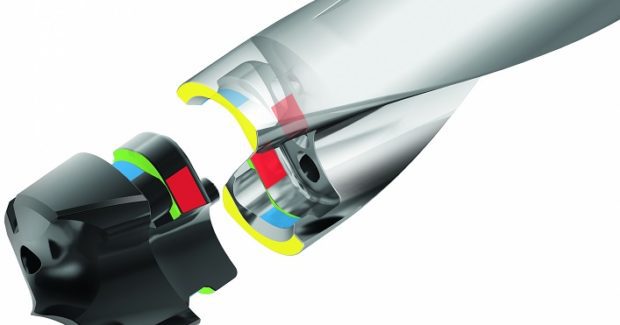

Some good ideas can be made even better. This was certainly the case when engineers from Kennametal Inc. (Latrobe, PA) took the strength and versatility of their proven KSEM modular drill system and combined it with the ease of use and low feed forces of its smaller companion drill, KenTIP. The resulting fusion of these advanced holemaking technologies is the KenTIP FS™, a 6 mm to 26 mm, 1.5xD to 12xD modular drill that’s simple to use, produces good hole quality, and is tough enough to compete with solid carbide drills across a wide range of materials. This modular drilling system has a full solid carbide front that is able to withstand more heat and abuse than competing modular drills. “FS denotes the ‘full solid’ carbide tip,” says Alexander Schmitt, a senior global product manager for modular drilling at Kennametal. “It looks like the tip of a solid carbide drill because the carbide tip fully covers and protects the steel holder from washing out. It not only looks like a solid carbide drill, it also works like one. This is a fusion of solid carbide’s best characteristics together with the cost-effectiveness of indexable drilling tools.”

The KenTIP FS appears to be like any other replaceable tip drill, with a disposable carbide insert, coolant through the tool, and a helical flute for efficient chip removal. However, its radically new design incorporates a number of important features. For starters, the flutes are smooth and shiny because they’re highly polished after final machining, a process that greatly improves chip evacuation and reduces wash out near the tip. Instead of the two coolant holes found in most modular drill designs, the KenTIP FS has four: two at the tip and two in the chip gullet directly behind the head. This “multicoolant” approach provides greater coolant volume to prevent chip packing while simultaneously drawing heat away from the cutting zone, prolonging tool life and improving hole quality.

“Multicoolant allows us to tailor the cutting fluid needs to the application,” explains Schmitt. “For example, adhesion and flank wear are a big concern in stainless steels and cast irons. Inserts with HPL and HPC point styles use through-the-tool coolant channels to provide better lubrication in this area to overcome the issue. In steel, however, it´s better to concentrate coolant to the rake and take the heat from the contact zone between chip and rake surface. So we eliminated the front coolant holes in our HPG geometry inserts to raise our insert tool life and improve chip breakage. In addition, this avoids built-up edge and makes the insert more rigid, which allows higher penetration rates in steel applications.”

Besides tuning the number of coolant holes in the insert, the HPG geometry is available in KCP15A, a new, highly wear-resistant carbide grade designed especially for steel. Its newly designed point angle and self-piloting chisel edge offer better positioning accuracy and hole straightness than other drills in this class, even under high feed rates. The insert corners are protected with small chamfers to reduce chipping and the margins are similarly reinforced, making the HPG geometry suitable for the cross holes and inclined exits encountered in hydraulics manifolds, for example, or the stacked plates used in heat exchanger production. If the world drilled only steel, HPG geometry inserts might be sufficient, but automotive manufacturers make extensive use of cast iron. For cast, ductile, and compacted graphite irons, the HPC geometry offers four margin lands and a radiused point that eliminates the exit chipping and cracking common with these materials, with a specially-designed chip gash that clears chips quickly in combination with the front coolant exits.

These insert styles have 143 deg points and specially prepared, polished or honed edges for maximum tool life to handle most anything a solid carbide drill can, but with far lower cost per part and equal or greater performance. A patented taper interface gives the KenTIP FS maximum rigidity and accuracy, with a retention lock that eliminates pullout. Its quick-release mechanism is familiar with users – just clean the pocket with an air blast, set the insert in place and give it a slight twist, then secure it with the supplied smart wrench. The large bearing surface can withstand extreme torsional loads without pocket deformation. Since the full solid carbide insert has no mounting screw, there’s no risk of damage to the clamping mechanism from chip or workpiece contact.

There´s no need for reconditioning the KenTIP FS as with solid carbide and many modular drills. Use the insert to its fullest capability, replace it with a fresh tool, and get money back when you recycle the old one using the Kennametal recycling service. There’s none of the offset adjustments as with re-sharpened tools, or worry about how a used drill will perform compared to a new one. Tool life and production throughput are more predictable and tooling costs are substantially reduced.

Automotive aluminum has met its match with the new KBDM face milling platform from Kennametal. Anyone who´s replaced a head gasket on an internal combustion engine knows a smooth, flat surface on both cylinder head and block is needed for proper operation. Manufacturers strive for predictable, controlled surface finishes and high production output, together with maximum tool life and the lowest tooling cost per machined component. Many machinists might think, “What´s the big deal? Aluminum is one of the easiest materials around.” While that is certainly true of the ubiquitous 6061-T6, nothing could be further from the truth when it comes to the aluminum alloys used in automotive applications: Grades 319 and 390, for example, are readily cast into the complex shapes needed for engine blocks, pistons, heads, pulleys, and similar parts, but due to their high silicon content – easily 20 to 30 times that of 6061 – they´re like cutting sand.

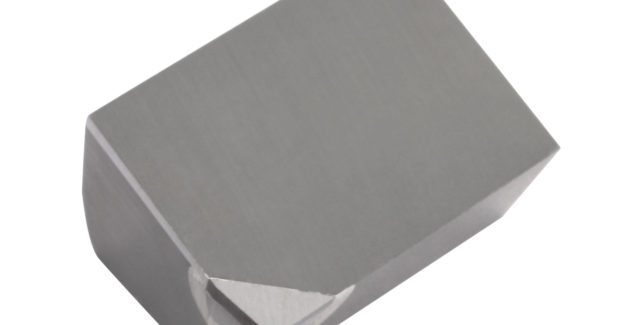

For those charged with machining these abrasive metals, the KBDM PCD face milling system is a better alternative than carbide cutting tools, one that produces mirror finishes and produces tens of thousands of parts per edge. “Finishes of 2 μm Ra to 3 μm Ra are easily obtainable, as is tool life between indexing of 40,000 engine blocks, cylinder heads, and other automotive components,” states Tim Marshall, a senior global product manager for indexable milling at Kennametal. “The KBDM PCD face milling platform uses a fine-pitch aluminum body with wedge-style clamps and adjustable pockets. A variety of polycrystalline diamond (PCD) inserts are available, from mini-tips for light finishing cuts to full face wipers, standard cartridge inserts, and ½ in (12.7 mm) axial cutters for heavy roughing and shoulder cutting.”

Designed for high volume machining, the KBDM is stocked in standard sizes of 2.5 in to 8.0 in (63 mm to 200 mm). “We can also offer cutters up to 21.5 in (550 mm) in diameter,” adds Marshall. “This allows users to machine very large components in a single pass. We also have options for integral shank bodies, HSK mounting, left hand cutter rotation, as well as special edge preps and nose radii.” Kennametal has also developed two PCD grades to complement this system for automotive jobs: KD1400 uses small diamond grains and offers excellent chipping resistance and good wear attributes, while KD1425 uses large diamond grains for excellent abrasion resistance and thermal stability, but only slightly lower performance where chipping is a concern. Both are capable of very high cutting parameters: depending on the alloy and setup rigidity, an initial cutting speed of 3,280 fpm (1000 m/min) and feedrates of .004 IPT (0.01 mm) are recommended, although substantially higher values are possible.

“One major machine builder conducted cutting tests against several competitive systems,” recalls Marshall. “Using a 24-tooth, 6.0 in (150 mm) diameter face mill at 80 percent radial engagement and 0.04 in axial DOC (1 mm), we ran at a feedrate of 0.006 in IPT (0.15 mm) and 9,600 fpm surface speed (2,926 m/min). This comes out to 6,112 rpm with a table feed of 880 ipm (22,350 mm) – it was really moving, and the KBDM produced a 14.7 Ra surface finish, several points better than the other cutting tools.”

Marshall recommends presetting the KBDM offline using an optical or video style presetter. A small amount of lubricant should be applied to the adjustment and locking screws, and also the wedge side of the pocket. Turn the axial adjustment screw until the insert is 0.0004 in to 0.0006 in (0.010 mm to 0.015 mm) below the final set height, tighten the locking screws to 31 in/lb (3.5 Nm) – don´t overtighten – then adjust each insert to its final height position. If using a wiper insert, set it 0.0006 in to 0.0008 in (0.015 mm to 0.020 mm) higher than the rest. “It´s simple to set up,” says Marshall. “You can easily get everything within a couple microns. That’s one of the keys to successful face milling, not only for proper balance at high spindle speeds, but also for achieving the desired surface finish. When you’re finishing a deck face on a block or head, both are critical.”

Kennametal Inc., 1600 Technology Way, PO Box 231, Latrobe, PA 15650-0231, 724-539-5000, www.kennametal.com.