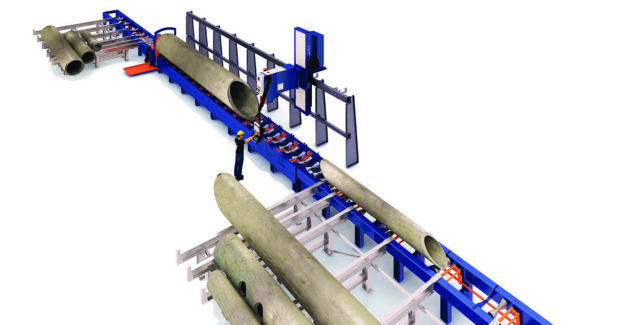

Automated Pipe Moving Logistics Combines with Highly Accurate Cutting

The SPC 1200 RB pipe cutting and 3D profiling machine from HGG eliminates cranes for material handling and ensures accurate, repeatable, on-the-fly measurement and compensation of longitudinal material movement during pipe rotation.

Posted: January 25, 2018

The new SPC 1200 RB pipe cutting and 3D profiling machine from HGG Profiling Equipment (Medina, OH) combines the logistics of an automated roller bed for moving pipes in and out, while incorporating a floating chuck for highly accurate pipe cutting precision and repeatability. The SPC 1200 RB easily accommodates pipe from 3 in to 48 in diameter, 20 ft to 40 ft long, with wall cutting accuracy up to 6 in thick.

SPC 1200 RB integration combines the benefits of two types of pipe cutting machines while eliminating a number of problems that affected productivity. With the logistics of in-feed and out-feed conveyors, this system eliminates the necessity for having to use cranes to move individual pipes in and out. Then, by integrating a chuck, users can count on accurate on-the-fly measurement and compensation of longitudinal pipe movement (creep) during rotation of the pipe, along with repeatability.

This pipe cutting machine is equipped with patented biaxial cutting heads that can be used to cut with either or both oxyfuel and plasma. Design flexibility enables the SPC 1200 RB to be configured to multiple layout combinations, allowing shops to fit the machine to a variety of floor space requirements and logistical flow. The machine also has integrated fume extraction built into the system: when connected to a proper dust collector, it easily draws most fumes out and keeps the shop virtually smoke-free.

HGG Profiling Equipment, 3977 Rivendale Drive, Medina, OH 44256, 330-461-6855, jt@hgg-group.com, www.hgg-group.com.