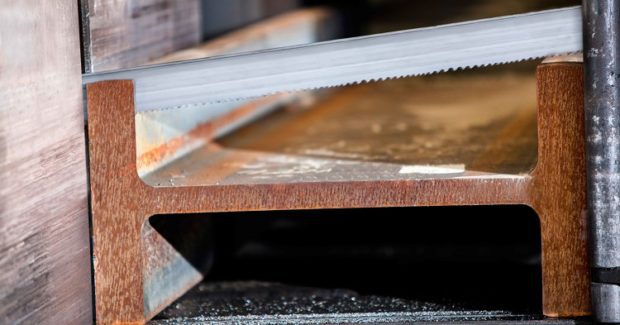

Bi-Metal Band Saw Solutions for Structural Cutting Applications

Cutting large structural beams and tubing can be a demanding application for metal fabricators. New innovations in bi-metal band saw blades can provide the cost-effective solutions they need to meet a range of specialty cutting applications.

Posted: January 19, 2018

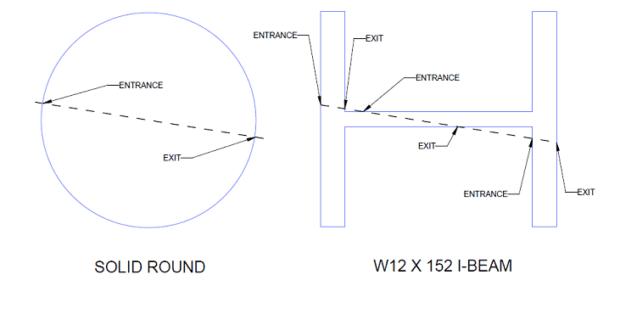

The growth of the global construction industry has highlighted some of the challenges that fabricators face when cutting large structural beams and tubing. The market for cutting these components is made up primarily of bi-metal band saw blades because of their ability to withstand the high forces and shock of the intermittent cut that is associated with beams and tubes. Specifically, structural cutting tends to be highly abusive to the individual teeth of a blade. Due to the shapes of the workpieces, a tooth will experience multiple “entrances/exits” as compared to the single entrance/exit seen in a solid cutting application. This is important because a tooth will experience an abrupt loading at each entrance, followed by the work of producing a chip in the workpiece, and a release at the exit (see Figure 1).

By increasing the number of these “shock/flex/release” cycles experienced per band revolution, the life of the individual teeth can be expected to decrease. The “shocks” at the additional entrances can be expected to correspond with an increased incidence of chipped teeth at the cutting edge, thereby reducing or eliminating the ability of teeth to form a chip. The additional “flex/release” cycles can be expected to promote fatigue failure at the bi-metal weld, resulting in stripped teeth. Larger structural shapes – particularly larger tubes – also feature one or more linear welds. These welds represent highly localized “hard” spots that can chip or strip teeth during cutting. Additionally, many structural shapes have significant residual stresses in the material – stresses that are relaxed upon cutting. This relaxation takes the form of expansion of material into the cut, trapping the blade, a phenomenon known as blade pinching. Blade pinching is a concern in many structural shapes, but particularly in the long web sections of deep I-Beams (greater than 30 in / 750 mm).

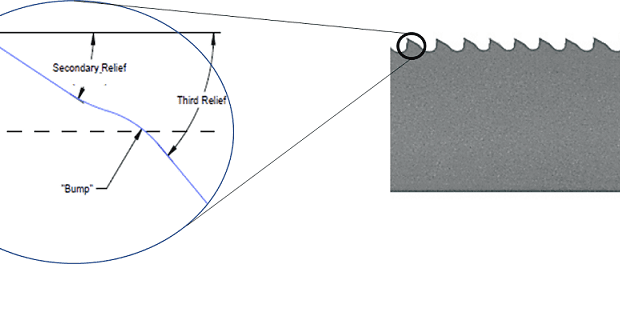

To address the challenges that fabricators face while maintaining blade life, the HRX™ Bi-Metal Band Saw Blade is engineered to cut structural steel, tubing and bundles, large metal beams and heavy walled tubes. Its patent-pending tooth design and wide-set profile help withstand the challenges of the intermittent cuts associated with these applications, delivering long blade life and straight cuts through wide cross sections. The initial relief is a shallow angle of a magnitude that has been shown to have increased resistance to tooth damage, while minimizing the tendency towards early crooked cutting. This portion of the geometry is brief, and transitions into a more standard relief angle to further limit early crooked cutting.

Following the secondary relief angle, a pair of radiuses produces a “bump” (see Figure 2). This feature is designed to have multiple performance benefits: First, it serves as a chip breaker, forcing the chip to curl away from the rake face of the tooth, both limiting damage to the rake face, and limiting the maximum size of the chip before it breaks. A second feature is that it serves to increase the size of the bi-metal weld interface. A third and larger design feature – the relief angle – leads into the gullet.

The HRX blade design also includes a multi-level set pattern that provides a wide cutting channel to help minimize blade pinching in highly stressed material. Finally, the blade features POWER BLAST TECHNOLOGY®, a proprietary process that strengthens the blade to minimize breaks. This process (which is also commonly used in the aerospace and automotive industries) adds a surface layer of compression that inhibits the formation of micro-cracks, which are the basis for larger cracks that cause instability and band breakage. All of these features combine to deliver a blade that is optimized to cut large beams and tubes, and structural shapes in common structural steels. (Note: For production cutting applications of solids and tubing in hardened steels, the QXP™ blade is recommended.)

As the demands of metal fabricators continue to evolve to meet global market needs, so do their requirements for metal cutting blades. Through constant innovation, bi-metal band saw blades can provide cost-effective solutions in a range of specialty cutting applications.