High-Feed Face Mill Speeds Up Productivity in Oil and Gas Work

Using a 25 deg entering angle for additional productivity gains when milling steel and cast-iron workpieces, the high-feed CoroMill 745 face milling cutter from Sandvik Coromant achieves higher metal removal rates in applications with depths of cut up to 0.110 in.

Posted: January 18, 2018

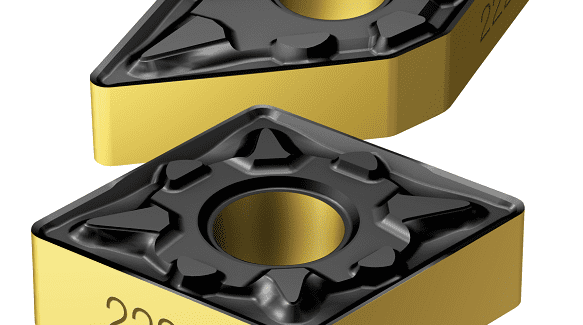

The high-feed version of the CoroMill® 745 face milling cutter from Sandvik Coromant (Fair Lawn, NJ) featuring a 25 deg entering angle for additional productivity gains when milling steel and cast iron workpieces. The new, high-feed version facilitates even higher metal removal rates (MRR) in applications with depths of cut up to 2.8 mm (0.110 in). This cutter is ideal for oil and gas, pump and valve, die and mold, automotive, power generation, and general engineering. Despite the elevated MRR and productivity, there is no compromise to surface finish when using the CoroMill 745. A light cutting action from the innovative insert positioning provides excellent chip formation, a smooth, soft sound, and low power consumption. “An important benefit of this cutter is the low cost per edge from its double-sided, 14-edge insert design,” says Matts Westin, a product manager at Sandvik Coromant. “In fact, purchasing departments will be pleased to learn that tool inventory costs are reduced because the CoroMill 745 with a 25 deg entering angle uses the same inserts as its counterpart cutter with a 42 deg entering angle.”

The high-feed CoroMill 745 is aimed at roughing to semi-finishing face milling operations on machining centers and multi-tasking machines. Its multi-edge concept is particularly suitable for large batch production, flexible transfer lines, and when maximum tool utilization is important. Advantages will be provided when milling components made from ISO P or ISO K materials, such as valves, engine blocks, hubs, main frames, pump components, and molds, in fact, any type of general engineering component. The presence of a short (0.6 mm, 0.024 in) parallel land ensures a good surface finish. The large screw ensures easy handling, while the insert position and the heptagonal insert shape make clamping exceptionally secure for reliable face milling operations. Internal coolant is available for all cutters that range from 63 mm to 160 mm (2.5 in to 6.0 in).

One user trial application showed impressive benefits when face milling a machine bed component made from cast CMC ST52 (165 HB) on an ISO 50 gantry mill. A 125 mm (5 in) CoroMill 745 with a 25 deg entering angle reduced cycle time per component by 40 percent compared with a competitor tool. The high-feed CoroMill 745 with a 25 deg entering angle complements the CoroMill 745 with a 42 deg entering angle.

Sandvik Coromant also offers a dedicated turning insert optimized for stainless steel materials that offers increased productivity, longer tool life, and higher machine utilization: the GC2220 provides major benefits to pump and valve manufacturers and general engineering shops serving the oil and gas industry. In response to common challenges associated with turning stainless steel workpieces, GC2220 is designed to offer higher resistance to plastic deformation and provide greater edge-line security. Plastic deformation takes place when the tool material becomes soft, typically as a result of elevated cutting temperatures. If a manufacturer is only machining two components before the insert needs to be replaced due to plastic deformation, then both productivity and profitability become compromised.

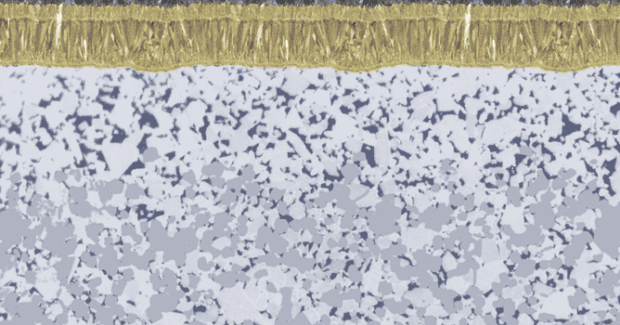

GC2220 is a CVD-coated, gradient sintered carbide that is designed specifically for semi-finishing to rough turning under stable conditions where higher wear resistance is required. Inveio™ coating is deployed to provide unidirectional crystal orientation in the alumina coating layer, delivering higher levels of wear resistance and tool life. This advanced and proprietary technology is supported by a columnar MT-TiCN inner coating that is hard and resistant against abrasive wear. As an added advantage of longer tool life, machine shops can reduce their cutting tool inventory. Users who benefit from this new grade are manufacturers tasked with external and/or internal turning operations in austenitic and duplex stainless steel components, such as pump housings, axles, shafts, seals, valves, and flanges. Other materials where the attributes of GC2220 prove advantageous include martensitic stainless steels and low carbon steels.

“For best practices, users should select the largest possible nose radius and always use coolant to decrease crater wear, notch wear, and plastic deformation,” explains Bimal Mazumdar, a product manager for turning at Sandvik Coromant. “And be sure to choose a dedicated insert grade for stainless steel to increase both tool life and production.” GC2220 is available for CoroTurn® 107 inserts that are designed for the internal and external turning of small or slender components, CoroTurn TR for external profiling, and T-Max® P for general turning applications.

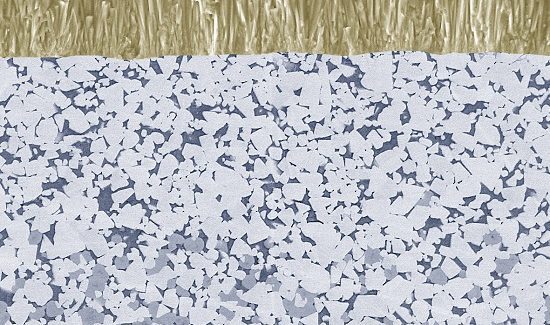

Sandvik Coromant also offers their GC4335 insert grade for turning steels in unstable conditions or where vibration issues prevail. It is designed to bring about secure and predictable machining as well as shorter cycle times and better machine utilization through reduced stoppages and longer insert life. Users benefit from an improved process with less risk of insert breakage, as well as reduced cost per component and faster return on investment. GC4335 also features Inveio coating technology for maximum thermal protection and offers greater steel turning endurance through improved edge-line security compared with the previous generation grade, along with greater resistance to flank wear, plastic deformation, and crater wear. “The GC4335 is particularly suited for turning uneven forged surfaces that can lead to frequent insert changes due to fatigue and failure,” notes Mazumdar. “Slowing down an operation to replace a broken insert means less production. When production is slower, fewer parts get completed per cycle and that affects overall profitability.”

GC4335 benefits subcontractors in the oil and gas sector, general engineering shops, as well as automotive OEMs and tier suppliers. Typical components include tubes, valves, crankshafts, differential housings, flanges, and rings to list a few. The underlying reasons behind the performance of this insert include a substrate that is well balanced between reliable toughness and resistance to plastic deformation. In addition, an alumina coating delivers efficient heat transfer from the cutting zone to act as a heat barrier, and the columnar MT-TiCN inner coating offers improved resistance against abrasive wear. A yellow TiN coating on the insert flank allows for easy wear detection.

One external face turning application in dry cutting conditions saw the GC4335 outperform a competitor insert on unalloyed steel (220 HB), delivering 3,647 completed components in comparison with just 1,980 (an 84 percent increase). The time-in-cut for this finishing operation was two seconds per component, while cutting speed was 145 m/min (475 fpm), feed rate was 0.4 mm/rev (0.016 in/rev), and depth of cut was 0.35 mm (0.014 in). The GC4335 assortment is available in T-Max P and CoroTurn 107.

Sandvik Coromant US, 1702 Nevins Road, Fair Lawn, NJ 07410-0428, 201-794-5000, Fax: 1-201-794-5157, www.sandvik.coromant.com.