How to Reduce Eye Strain by Optimizing Contrast and Clarity in Welding and Light States

To achieve the perfect weld, operators must be able to clearly see their work. This new lens technology from Miller Electric optimizes contrast and clarity in both welding and light states so that operators see natural color tones and get a crisp, high-definition view of the workpiece.

Posted: January 12, 2018

Miller Electric Mfg. Co. (Appleton, WI), a leading worldwide manufacturer of arc welding equipment, is expanding their ClearLight Lens Technology to all digital welding helmets. ClearLight optimizes clarity for welding operators so that they can produce better welds with less rework. “To achieve the perfect weld, operators need to be able to clearly see their work. This lens technology optimizes contrast and clarity in both welding and light states so that operators see natural color tones and get a crisp, high-definition view of the workpiece,” said Sam Harvey, the product manager of welding safety and health at Miller Electric. “This innovative helmet technology reduces eye fatigue, increases productivity and improves performance.”

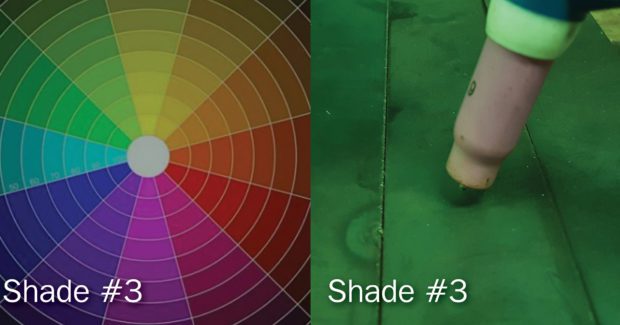

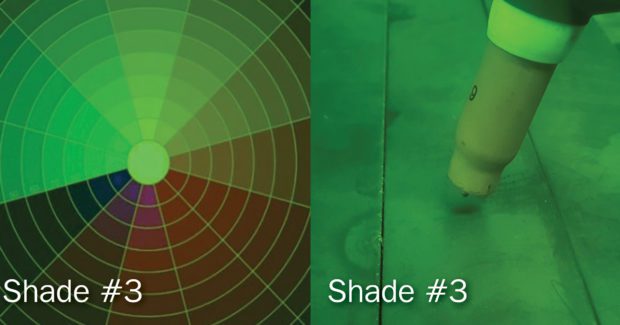

ClearLight Lens Technology enhances clarity by allowing more colors to come through the lens. Where other lenses often produce a view with a greenish-yellow or blue tint, this lens provides truer colors during welding. This means operators see more contrast among objects in the viewing area, resulting in reduced eye strain and fatigue. In addition, the 1/1/1/2 optical clarity rating of ClearLight lenses allows a true 3.0 light state. This brighter light state when the operator isn’t welding enhances the ability for operators to keep their hood down as much as possible, which improves safety and productivity.

https://youtu.be/YbMFC-Q6xwY

Previously only available in Miller® T94™ Series auto-darkening helmets, ClearLight has now been expanded to all Miller digital helmets to include Digital Infinity™, Digital Elite™ and Digital Performance™ models.

Miller Electric Manufacturing Co., 1635 West Spencer Street, PO Box 1079, Appleton, WI 54912-1079, 920-734-9821, www.millerwelds.com.