Multi-Tasking Dual Station Abrasive Pipe Notcher Increases Shop Productivity

The JET Dual Station Abrasive Pipe Notcher from JPW Industries uses an innovative two-station design for quick and easy access to notching, grinding and deburring at three different work stations. Seven interchangeable rollers come standard and require no tools to install.

Posted: January 10, 2018

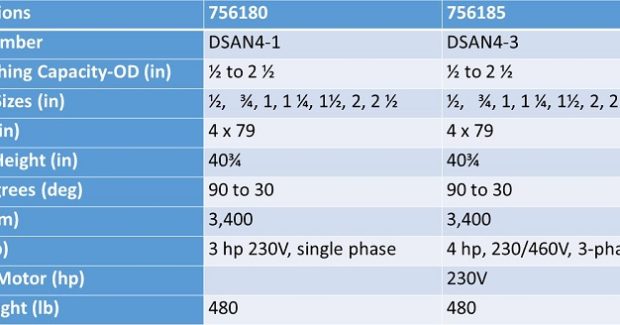

The JET® Dual Station Abrasive Pipe Notcher from JPW Industries, Inc.® (La Vergne, TN) does extra duty to maximize shop productivity and output with an innovative two-station design that provides quick and easy access to notching, grinding and deburring at three different work stations. The Dual Station Abrasive Pipe Notcher is made to last, with heavy gauge steel construction throughout. This multi-tasking machine is engineered to notch pipe from ½ in to 2½ in diameter at the front station, and it can notch angles from 90 deg to 30 deg by use of a multi-positional hand lever vise. Seven interchangeable rollers come standard and require no tools to install. Mandrel sizes include ½ in, ¾ in, 1 in, 1¼ in, 1½ in, 2 in and 2½ in. Rollers are conveniently stored in an onboard compartment at the machine’s base. A forward/reverse switch changes belt direction, allowing the operator to switch from notching to standard grinding at the rear of the machine. For grinding large parts, a hinged top cover opens to provide access to the entire length of the 4 in x 79 in belt surface. Three replacement belts of 36 grit, 60 grit and 80 grit and a belt guard come standard.

A safety shield and two 3 in dust ports help direct sparks and debris away from the operator. The dust ports mount easily to a metalworking dust collector. This versatile abrasive notcher is powered by a totally enclosed, fan-cooled AC induction motor rated at 3 hp or 4 hp with a speed of 3,400 rpm. The machine is available in single- or three-phase models to allow installation in different shop environments. A safety switch on the power key helps prevent accidental start-ups. This notcher is CSA/US certified. The Dual Station Abrasive Pipe Notcher-1Ph (756180) and Dual Station Abrasive Pipe Notcher-3 Ph (756185) are covered by a two-year warranty, as well as RED AssuranceTM, one of the industry’s most dependable service and support guarantee programs. For pricing information, visit your nearest JET dealer.

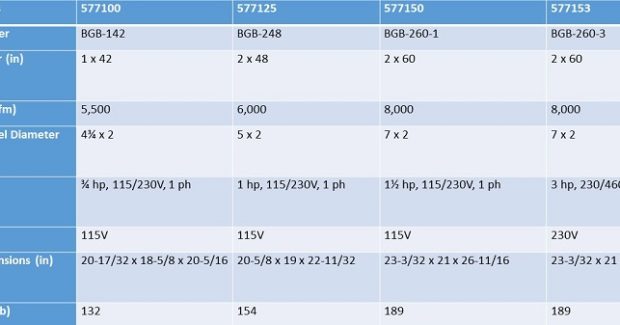

JPW also offers JET Three Wheel Belt Bench Grinders that are ideal for grinding castings or deburring and finishing ferrous and non-ferrous metal parts. To accommodate a wide range of grinding needs on either flat or angular surfaces, these powerful belt grinders come in three sizes, including 1 in x 42 in, 2 in x 48 in and 2 in x 60 in belt diameters. They are built for the long haul with heavy duty, casted bodies and die casted belt levers. A vented full motor shroud keeps dust and chips away from the motor shaft. The motor is also protected by a thermal reset to prevent overheating. The three-wheel design provides optimal grinding surfaces. Abrasive belts are equipped with urethane drive and idle wheels for dependable and long lasting service. An intuitive lever-based belt tensioning process makes belt changes quick and easy. Large throat clearance is provided, both vertically and horizontally, for grinding large and odd-shaped parts. Adjustment of the tool rest and platen are tool-less to save operator set up time.

Safety measures include an innovative dust port that directs sparks to the rear of the grinder and away from the operator. The 3 in dust port mounts easily to a metalworking dust collector. Also, the power switch has a safety key to prevent accidental startups. All three belt grinders are CSA/US certified and are driven by motors ranging from ¾ hp to 3 hp with constant belt speeds of 5,500 to 8,000, respectively. The 2 in x 60 in machine is available in single- or three-phase models to allow installation in different shop environments. The 1 in x 42 in (577100), 2 in x 48 in (577125), 2 in x 60 in single-phase (577150) and 2 in x 60 in three-phase (577153) machines are covered by a two-year warranty and the RED Assurance service and support guarantee program.

JPW also offers the JET 8 in Industrial Buffer, a 44 lb benchtop dynamo with an entire body constructed of cast iron and a fully-enclosed industrial housing with factory-sealed, pre-lubricated ball-bearings for reliable, long life use. Rubber mounts at the buffer’s base help eliminate movement, plus dampen vibration. This buffer was designed with operator safety in mind: its motor includes brake resistors to shut down the wheels’ rotation so that they come to a complete stop in less than 20 seconds. The variable-speed motor operates from 900 rpm to 3,600 rpm. Plus, there’s no on/off rocker switch: the power interface features an electronic touch pad panel with a power on/off control, flanked by up and down arrows to adjust and monitor the buffer’s speed. The 1 hp buffer operates on prewired 115V current with a 230V option. The buffer has a standard 5/8 in shaft with 8 x 1/2 in buffing wheels. It also incorporates spiral and half-spiral buffing wheels.

The 8 in Industrial Buffer has received CSA/US certification in meeting strict safety guidelines and electrical requirements. Whether it’s buffing the high and low spots in metal or creating a mirror finish in aluminum, stainless steel, brass or copper, this buffer is up to the task. Optional accessories include a Pedestal Stand (578172), Gooseneck Lamp (578100) and a Four Bar Buffing Compound Kit (577117). The JET 8 in Industrial Buffer (578218, model no. IBG-8VSB) includes two buffer wheels and is covered by a two-year warranty plus the RED Assurance program. For pricing information on all of this equipment, visit your nearest JET dealer.

JPW Industries, Inc., 427 New Sanford Road, La Vergne, TN 37086, 615-793-8900, Fax: 615-793-8905, www.jettools.com, www.jpwindustries.com.