The Move from Billet Work to Bar Fed

To replace some outdated equipment and upgrade their manufacturing capabilities, this machine shop invested in a universal turning center that gave them the opportunity to bid for larger work at a competitive cost. Now it provides the capacity they need to absorb the increasing workload they are experiencing through winning more business.

Posted: January 17, 2018

Mil-Tu-Fit Engineering (Bristol, England) has been manufacturing precision components for oil and gas and other industries for over 40 years. Along with machining, their Bristol factory also offers laser cutting, surface treatment and welding that enable them to supply complete high quality assemblies to their customers. Machined parts are generally under 125 mm diameter, with low batch quantities from just one or two parts up to around 100 parts. The most commonly machined materials are 303 grade stainless steel and plastics. “Some of our existing machinery was reaching the end of its useful life and we needed to replace it and, at the same time, upgrade our manufacturing capabilities,” said Paul Beattie, the production manager at Mil-Tu-Fit.

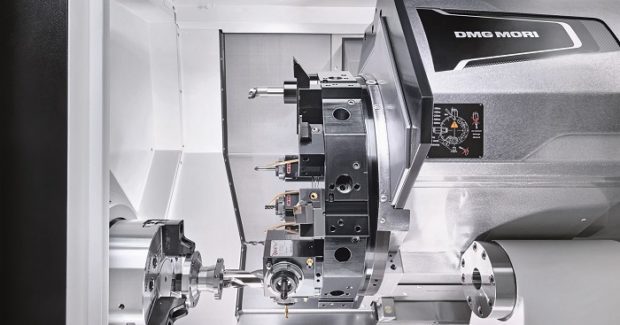

The company evaluated a range of machine tools. The main criteria were 4th axis and driven tools, the spindle diameter, the number of tool stations in the turret, accuracy and ease of programming. “Simplicity of programming on the machine was a major consideration because with small quantities we needed to be able to complete this task quickly and be sure it was right first time,” noted Beattie. “I was familiar with the Siemens control on the CLX 450 universal turning center from DMG MORI UK (Coventry, England) and had absolute confidence in the system. Programming the Y-axis and the driven tools can be done easily, and the verification and graphics check ensure a reliable milling and turning toolpath.” They purchased a CLX 450 fitted with a bar feeder that can feed 80 mm diameter through the spindle, giving them the opportunity to bid for larger work at a competitive cost.

“The large 80 mm bar feed appealed to us because that means parts which were previously billet work can now be bar fed,” added Beattie. “Previously we often had to carry out turning and milling operation on multiple machines, but we now combine the operations on the CLX 450, with many parts coming off the machine completed in one hit. Along with manufacturing parts around 20 percent quicker, we also save on material handling, we only have to set up one machine, and fixtures for different operations have been largely eliminated.” Along with these savings, the shop also reports that their parts are more accurate, with better concentricity and parallelism, and that tool life has improved. “The operating system is user friendly, and the machine has very good reliability and a small footprint,” continues Beattie. “Overall, the price of the machine was very attractive, availability was within three months and some other blue chip companies convinced us we were making the right decision.”

Since the company installed the CLX 450 it has seen an increase in its order books from existing customers. It has been winning more of the work it is bidding on and, because of the machine, it has increased capacity that enables the shop to maintain short delivery schedules. “This machine has certainly lived up to our expectations,” stated Beattie. “We needed to maintain our competitive lead, and our customers definitely appreciate our investment in advanced technology. We now have the capacity to absorb the increasing workload we are experiencing through winning more business. This is a major step forward in our manufacturing capabilities.”

Mil-Tu-Fit Engineering Ltd, 246 Broomhill Road, Brislington, Bristol, England BS4 5RG, 0117 971 7234, Fax: 0117 971 4789, info@miltufit.co.uk, www.miltufit.co.uk.

DMG MORI USA, 2400 Huntington Boulevard, Hoffman Estates, IL 60192, 847-593-5400, us.dmgmori.com.