Bladderless Fluid Forming of Seamless, High Pressure Metal Tubing

The FormBalancer FB42 from FluidForming Americas can create larger single prototypes or oversized high-run parts of titanium, aluminum, stainless steel, and copper that require an extra-large 47 in square forming table capacity.

Posted: February 22, 2018

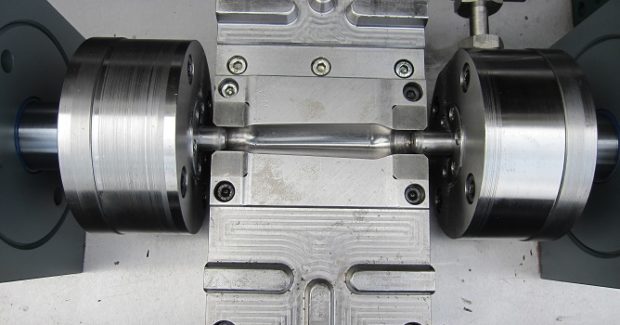

FluidForming Americas, LLC (Hartsville TN), a premier engineer in bladderless fluid forming technology, has integrated a long sought-after seamless, high pressure metal tube forming capability into the intricate sheet metal forming operations of their FormBalancer machine. “This integrated high pressure tube forming capability is manufacturing innovation at its highest level. Never before has a prototype and production fluid forming machine been so versatile. We are pleased to present this industry-first to the ever cost-conscious manufacturing market,” said Paul Benny, the president of FluidForming Americas. FormBalancers replace antiquated and cost-intensive die stamping processes and legacy-style “bladder forming” with the single-step bladderless fluid forming of intricate, complex parts that have less metal fatigue. They utilize forming pressure up to 60,000 psi to create complex parts at lower costs in a wide variety of metals, such as titanium, aluminum, stainless steel, and copper, without the use of trouble-prone bladders. They can achieve a minimum radii of 1.5 times the material thickness.

These machines are capable of virtually distortion-free forming of intricate pre-brushed and pre-patterned surfaces, a breakthrough in advanced metal forming technology that is achieved by varying the bladderless forming process pressures throughout the duty cycle. Because the water pressure side is friction-free, it prevents marring the detailed finish of brushed and patterned sheet metal. The resulting finished parts exhibit completely distortion-free surface patterns that can eliminate multi-step traditional metal forming processes in many cases, and at substantial cost savings. Even with this exciting new tube forming capability, the FormBalancer retains its compact design. The machine does not need a special hardened foundation or ceiling heights over 15 ft.

These machines are available in four space-saving models, with forming table sizes ranging from 32 in square to 59 in x 71 in, and forming depths from 12 in to 26 in. This includes one of the largest and most capable bladderless fluid forming machines available on the market, the FormBalancer FB42, which offers the ability to create larger single prototypes or oversized high-run parts that require the extra-large 47 in square forming table capacity. FormBalancers have seen increased usage in the automobile, aerospace, and medical industries. “Being able to design, model and produce a wide variety of complex parts opens up incredible opportunities for shops to reduce their cycle times, explore previously untapped product opportunities and grow their revenue and profits with the cost savings inherent in this streamlined process,” added Benny.

FluidForming Americas, LLC, 295 Trousdale Way, Hartsville, TN 37074-2073, 800-497-3545, www.ffamericas.com.