Cutters and Inserts for Machining Turbine Components Used in Power Generation

The R217/R220.28 cutter from Seco Tools performs cost effective face milling, slotting and contouring in ISO M and ISO S materials, as well as some difficult-to-machine ISO P materials, such as martensitic stainless steel.

Posted: February 15, 2018

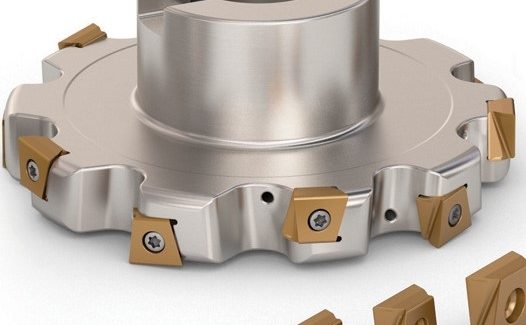

The R217/220.28 cutter from Seco Tools, LLC (Troy, MI) uses a completely new body design that incorporates double-sided round inserts to deliver cost effective performance and boost productivity significantly. Double-negative-positioning pocket seats of the R217/R220.28 cutters enhance cutting capabilities and enable safe, user-friendly indexing that saves time and provides trouble-free operation. The R217/R220.28 performs face milling, slotting and contouring in ISO M and ISO S materials, as well as some difficult-to-machine ISO P materials, such as martensitic stainless steel. The cutter excels in Z-leveling applications and is ideal for machining turbine blades for the power generation industry. The range for this cutter includes diameters from 1.25 in (32 mm) to 4.00 in (100 mm) for normal and close pitch versions. The 12 mm IC inserts are available in PVD and CVD grades with two different geometries for varying applications.

For machining a wide range of components used in power generation turbine segments, Secomax™ CS300 ceramic inserts and cutter bodies boost productivity in milling and turning operations with heavy interrupted cuts on nickel-based heat-resistant superalloys (HRSA) that increase productivity by up to eight times over standard carbide milling. CS300 inserts are SiAlON-type ceramics that offer high notch wear resistance, toughness and thermal shock resistance. These inserts provide optimum flank wear resistance at higher cutting speeds ranging from 1,970 fpm to 3,940 fpm (600 mpm to 1,200 mpm) and enable feeds from 0.002 in to 0.006 in (0.05 mm to 0.15 mm) per tooth. Combined, these attributes reduce machining cost per workpiece, increase output and lower energy consumption.

https://youtu.be/lx6tphqH4KE

The R220.26 and R217.26 cutter bodies are hardened and nickel-coated for high reliability, reduced chip friction and better resistance to high temperatures. Wedge clamps provide more secure insert locking and feature internal air coolant channels that ensure optimum chip evacuation and heat control. The metric range includes cutter bodies with RP 1204 inserts for facing and pocketing in diameters from 32 mm to 50 mm. Cutters with RN 1207 and RN 1204 inserts for facing are available in diameters from 32 mm to 125 mm. The imperial range includes 2.0 in, 2.5 in and 3.0 in diameters.

For machining wind power components, the family of 335.25 disc milling cutters has added 9 mm and 12 mm sized XNHQ inserts for cutting widths from 0.531 in to 1.26 in (13 mm to 32 mm) for an even greater variety of applications. The versatile 335.25 disc milling cutter performs slotting, back facing, helical and circular interpolation and plunging operations. Incorporating a unique cutter design and insert geometry with four cutting edges, the 335.25 reduces cutting forces and optimizes chip flow to ensure reliable and productive machining. The line features both fixed-pocket and adjustable-width versions to accommodate all production environments. Available in diameters ranging from 4.00 in to 12.00 in (80 mm to 315 mm), the 335.25 line includes 0.75 in and 1.00 in (15 mm, 20 mm and 25 mm) cutting widths for the fixed-pocket version and from 0.531 in to 1.26 in (13 mm to 32 mm) cutting widths for the adjustable-pocket version.

Inserts are offered in four sizes with corner radii from 0.016 in to 0.236 in (0.4 mm to 6.0 mm). Additionally, the range of insert grades available allows the 335.25 to be applied to all material types and each insert reduces costs by offering four cutting edges, two left-hand and two right-hand.

Seco Tools, LLC, 2805 Bellingham Drive, Troy, MI 48083, 248-528-5451, www.secotools.com/us.