How to Get Higher Welding Output from a Smaller Area

The IRB 2600ID robot from ABB Robotics achieves maximum acceleration at all times without restriction to significantly reduce total welding cycle times and increase reliability.

Posted: February 26, 2018

The compact IRB 1660ID robot from ABB Robotics (Auburn Hills, MI) is the most versatile robot in the mid-size class for arc welding and machine tending applications. Its Integrated DressPack (ID) design makes it easier to program and simulate predictable cable movements than standard robots with externally routed cables. Its decreased cable wear and damage reduces maintenance costs by 50 percent, and its small footprint allows for more efficient robot cell layouts, saving valuable space on the factory floor. To meet the growing demand for superior and even quality in arc welding applications, the IRB 1660ID features a stronger, more rigid upper arm with a reach of 1.55 m and a payload of 6 kg to accommodate heavier weld torches and provide improved wire feeding control near the arc to guarantee high volume production. This, combined with TrueMove™ technology and the new motion process “Accuracy mode,” provides 0.05 mm path repeatability for excellent welding results.

The Integrated DressPack allows the robot to move at maximum acceleration and speed, enabling fast and reliable movements ideal for machine tending applications. The risk of collision in confined spaces is also eliminated, and the combined 1,390 deg working range of axes 4, 5 and 6 provides outstanding agility inside CNC machines. The IRB 1660ID includes a new generation of accurate, efficient and reliable motors.

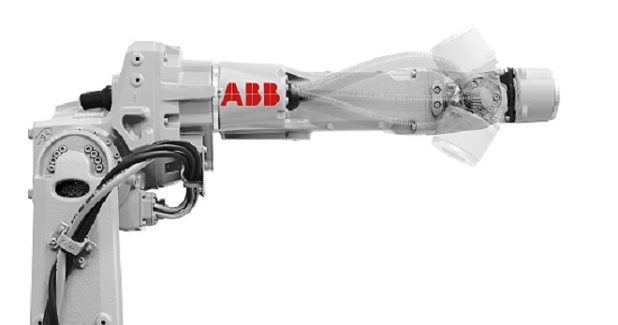

The IRB 2600ID robot features a unique combination of high payload capacity, large working range and Integrated Dressing (ID) that routes all cables and hoses inside the robot’s upper arm and wrist. These robots can reduce cycle times by up to 15 percent and significantly increase production output in arc welding, materials handling and machine tending. Because all of the process cables and hoses are routed inside the robot arm, IRB 2600ID robots dramatically decrease downtime caused by interference and wear. This integration also ensures that the maximum achievable acceleration is available at all times without restriction. These features help to significantly reduce total cycle times and increase reliability. There are two models in the range: the 2.00 m reach, 8 kg version is designed to be integrated with arc welding process equipment. The 1.85 m reach, 15 kg model comes with a flexible conduit designed to optimize materials handling and machine tending applications.

https://youtu.be/wNvXwASdufk

The ease with which off-line programs can be created is enhanced with ID. The controlled movements of the hoses and cables are easily predicted, so programming and simulations are perfect representations of the actual robot system. This minimizes the time required for fine-tuning programs and enables a faster start of production. Total programming time is reduced by up to 90 percent. With all of the hoses and cables firmly secured and protected, they swing less during operation and, with less exposure to weld spatter or cutting fluids, the lifetime increases significantly. Costs are reduced in terms of purchasing and exchange by up to 75 percent, and up to three production stops per year can be eliminated. With its compact design and without loose hoses and cables, the IRB 2600ID has a very small footprint with a swing base radius of only 337 mm and a base width of only 511 mm. In arc welding, the reduced risk of interference with other robots allows for productive, high density installations with 50 percent more robots and up to 50 percent higher output from a production cell.

In material handling and machine tending, this small footprint means that the robot can be placed closer to the machines being served. The wrist on the IRB 2600ID is very slim, only 227 mm x 130 mm. With all of the hoses and cables integrated through the process wrist, the robot can easily access narrow openings and perform complex movements. For example, in arc welding this means that the IRB 2600ID can do circular welds without interruption and without compromising quality – in a much shorter cycle time – thereby increasing production output.

ABB Robotics – North America, 1250 Brown Road, Auburn Hills, MI 48326-1507, 248-391-9000, www.abb.com/robotics.